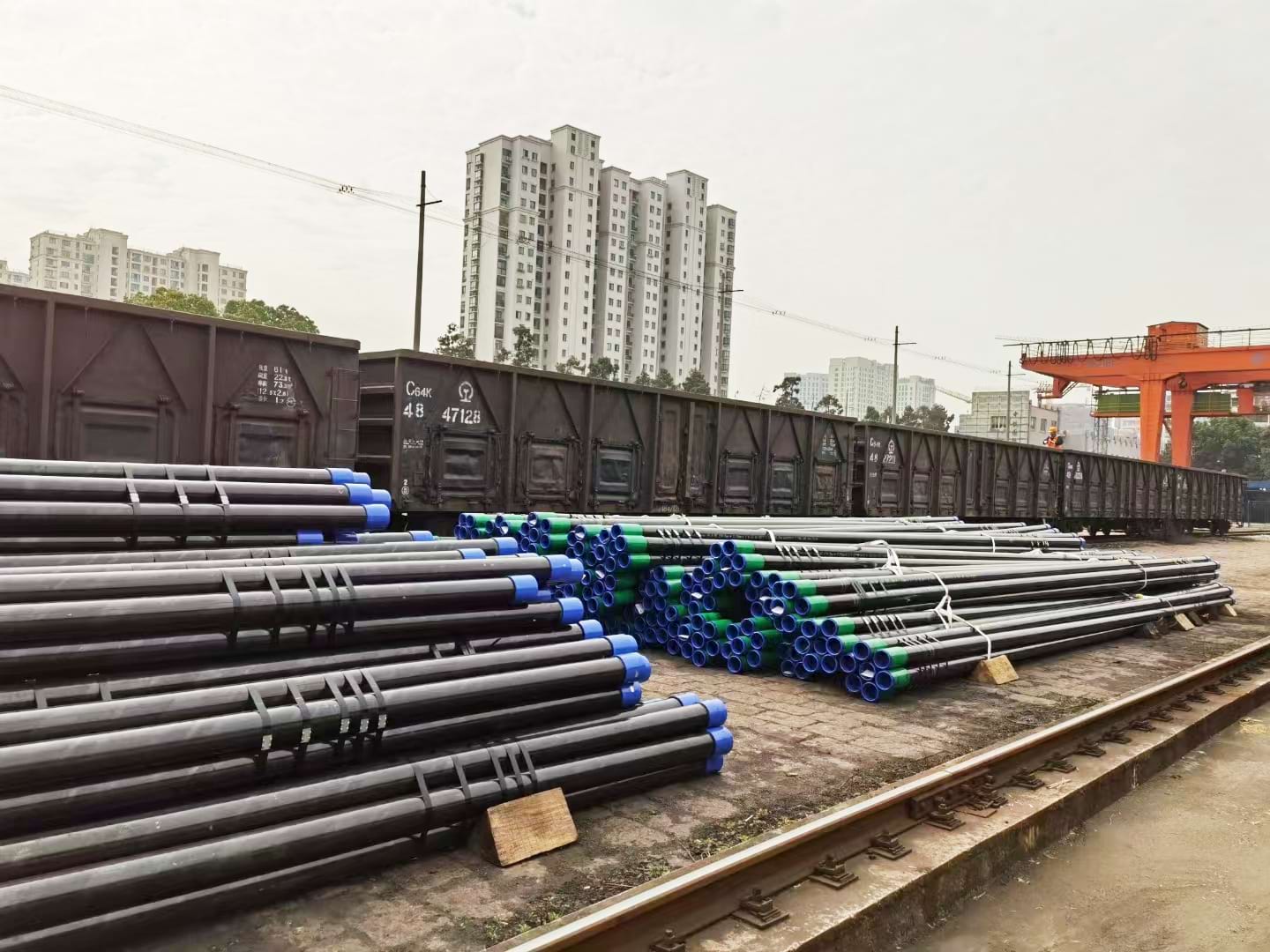

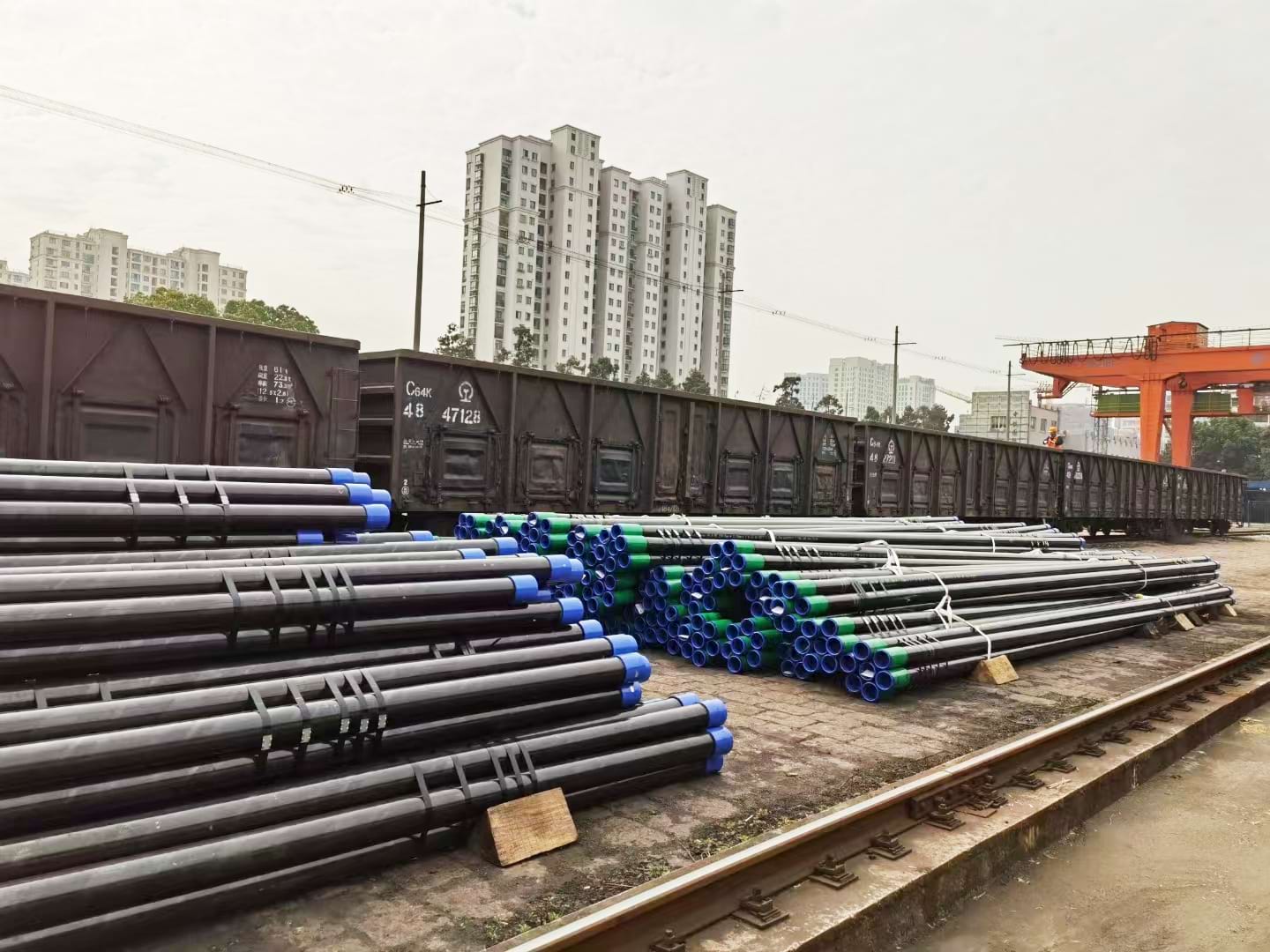

Application Of Casing&Tubing

Oil casing steel pipes are specialized pipes used in the oil and gas industry for drilling, completing, and producing oil and natural gas wells,which are typically made of high-strength carbon or alloy steel and come in various sizes and dimensions to suit different well specifications.

Oil tubing steel pipes is a type of steel pipe designed for the extraction of oil and gas from wells, which are particularly used in the production phase of oil and natural gas wells,with smaller diameters compared to casing pipes. Tubing pipes are installed inside casing pipes and extend from the wellhead to the bottom of the well, serve as conduits for the transportation of oil, natural gas, and other fluids.

Specifications Of Casings

OD: 4.5’’ to 20’’

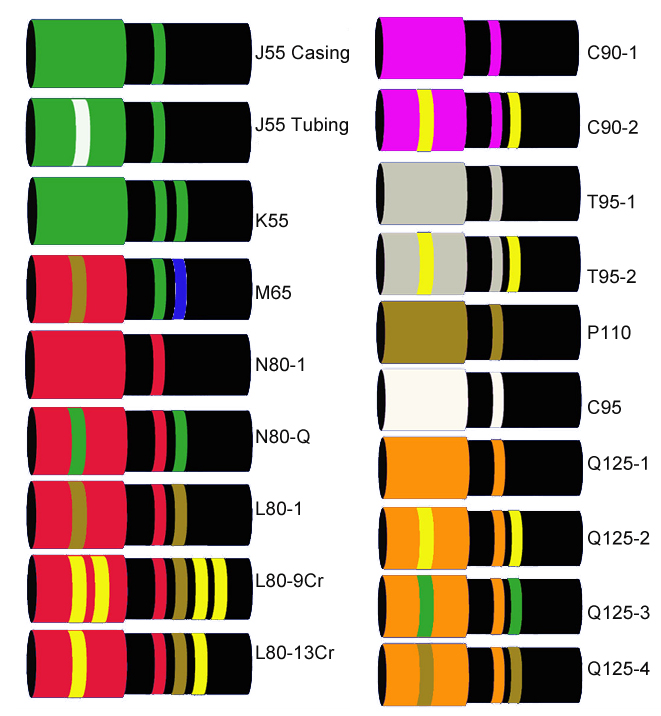

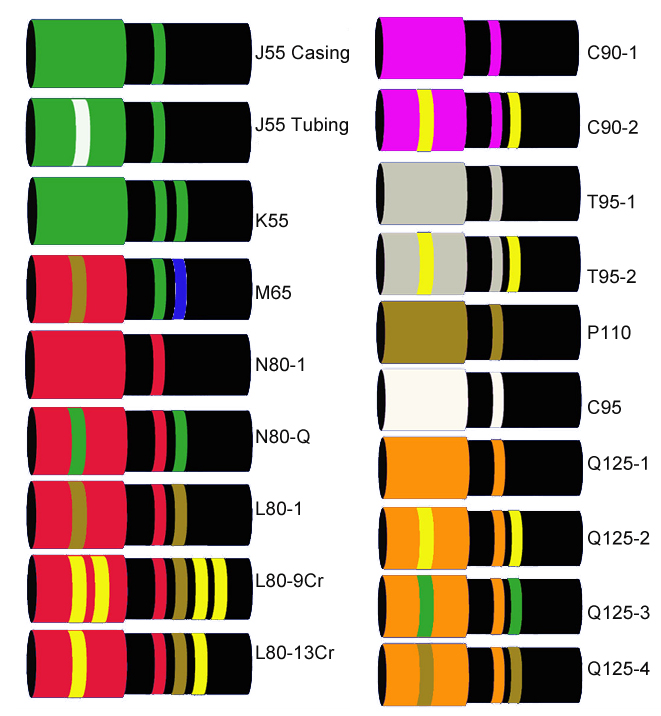

Grade: J55, K55, N80, L80, P110, Q125, V150, L80-1Cr, L80-3Cr, L80-9Cr, L80-13Cr

Standard: API 5CT

Connection: P(Plain end), STC (short threads), LTC (long threads), BTC (buttress threads), premium connection

Length: Range3

Product Specification Level: PSL1, PSL2, PSL3

Specifications Of Tubings

OD: 1.9’’ to 4.5’’

Grade: J55, K55, N80, L80, P110, Q125, V150, L80-1Cr, L80-3Cr, L80-9Cr, L80-13Cr

Standard: API 5CT

Connection: Non-upset ends (NUE), External upset ends (EUE) premium connection

Length: Range2

Product Specification Level: PSL1, PSL2, PSL3

Color Ring On Casing&Tubing

Sulfur Corrosion Resistant&High Collapse Casing And Tubing

Sulfur corrosion-resistant and high-collapse casing and tubing are specialized materials used in the oil and gas industry, particularly in environments where high levels of sulfur are present. These materials are typically made from special alloys that are highly resistant to corrosion in the presence of sulfur compounds. Common alloys include chromium, nickel, and molybdenum.

Grades Of Chrome Casing&Tubing: 1cr, 3cr, 9cr, 13cr, super 13cr(chrome, 1%cr, 3%cr, 9%cr, 13%)

Grades Of Sulfur Corrosion Resistant Casing&Tubing: 80SS, 95SS, 100SS, 110SS

Grades Of High Collapse Casing&Tubing: 80HC, 95HC, 110HC, 125HC, 140HC

*upon technical agreement with clients to meet different demand of materials

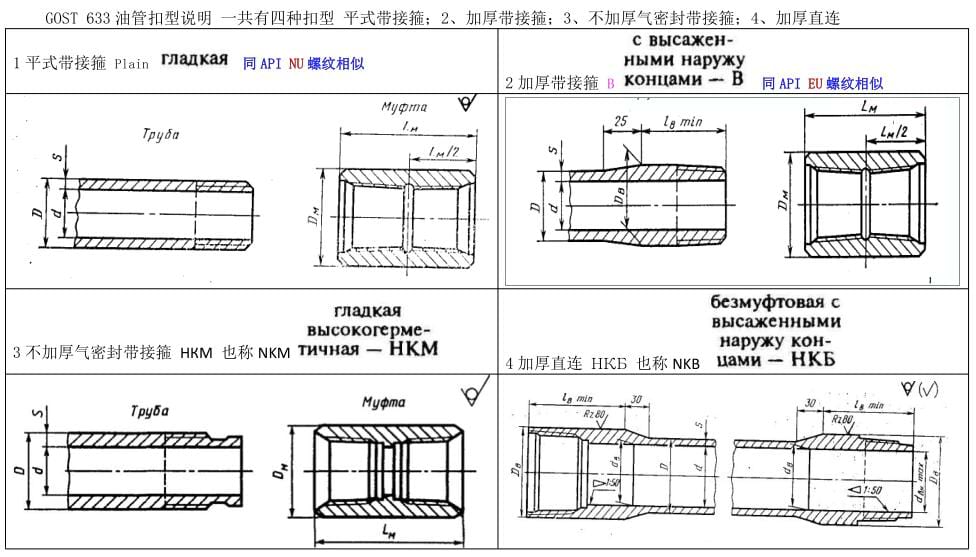

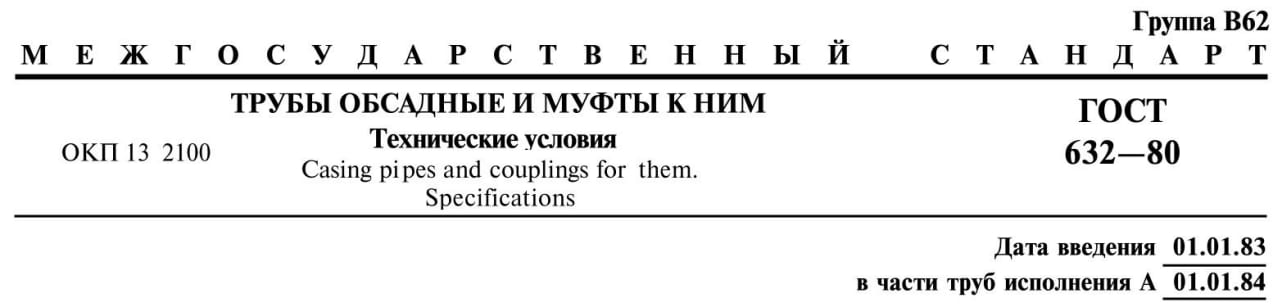

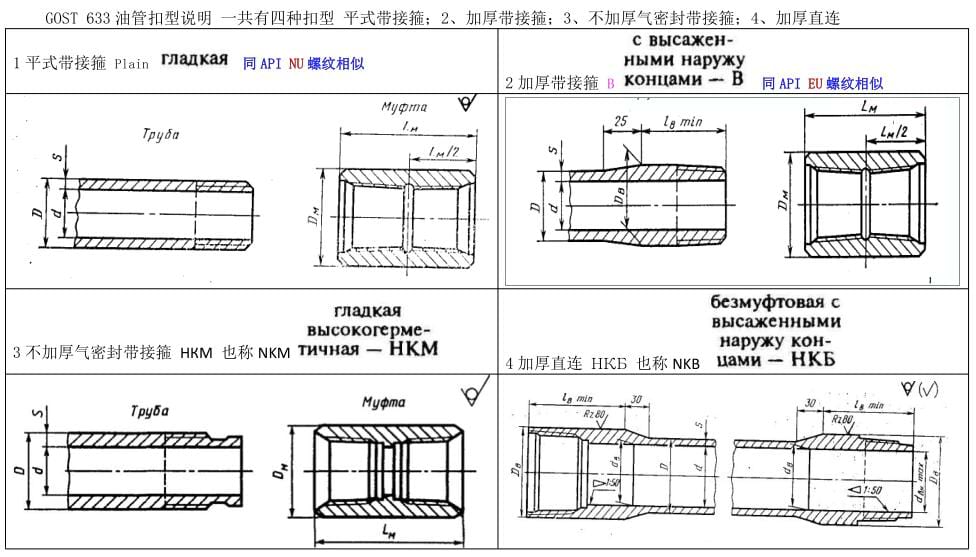

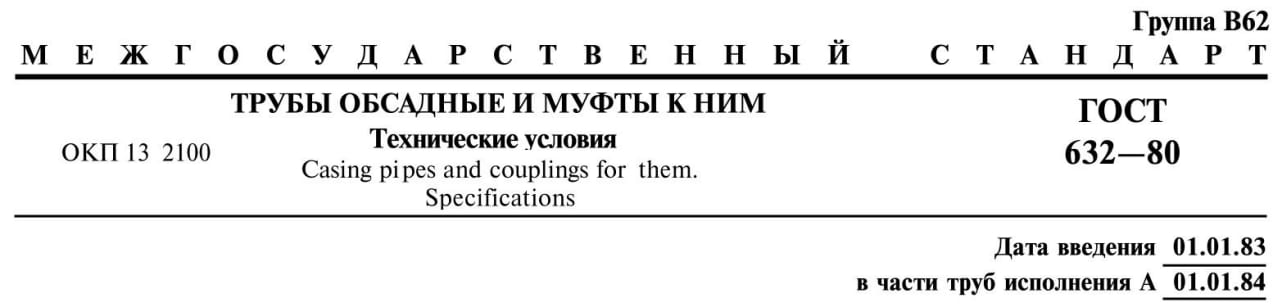

GOST Casing&Tubing

GOST standard(GOST 632, GOST 633, GOST 8645) is standard of casing&tubing mainly used by middle Asian countries.

Connection:

Casing: OTTM&OTTG

Tubing: NU&EU