Features Of Seamless Precision Tube

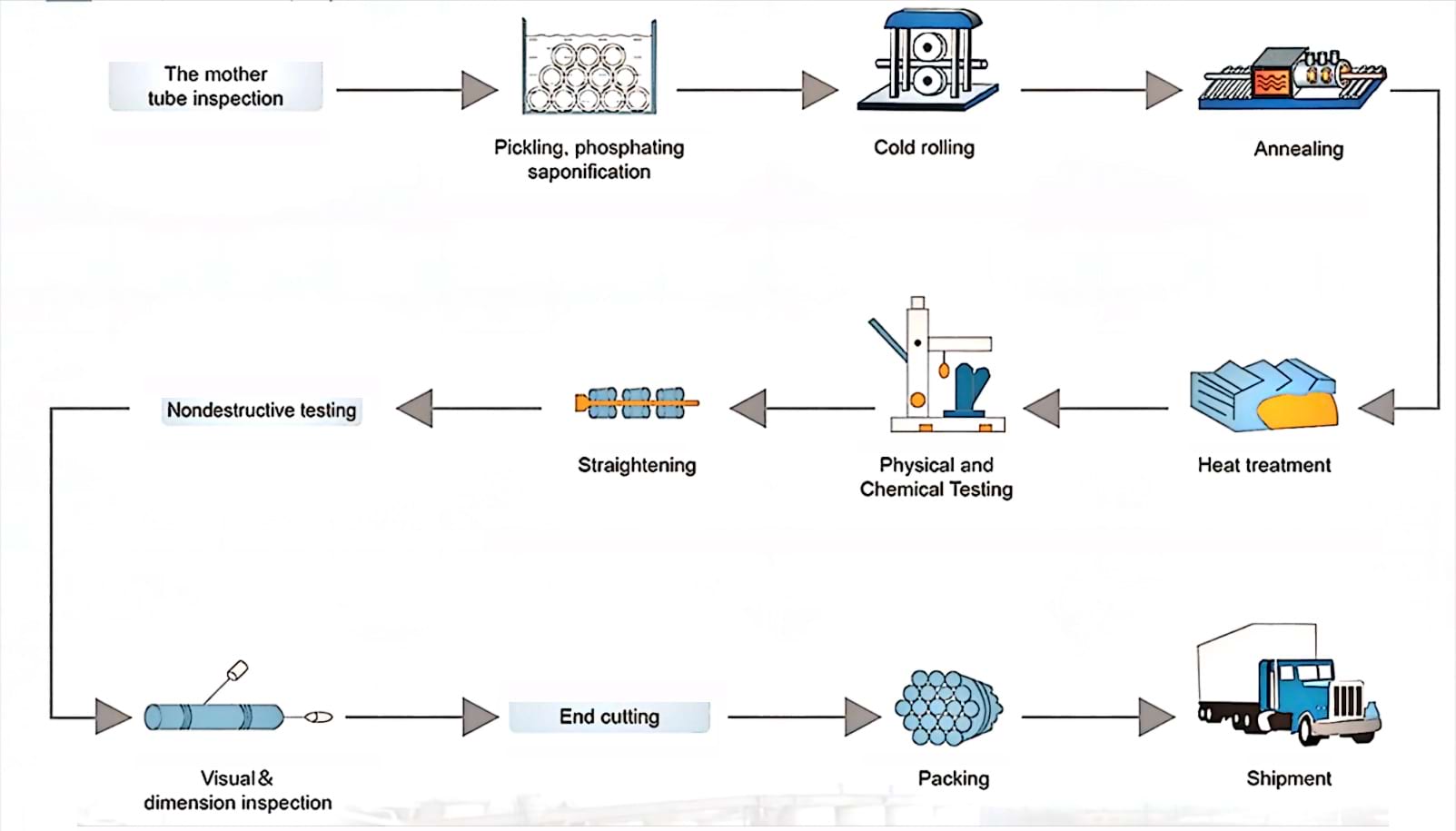

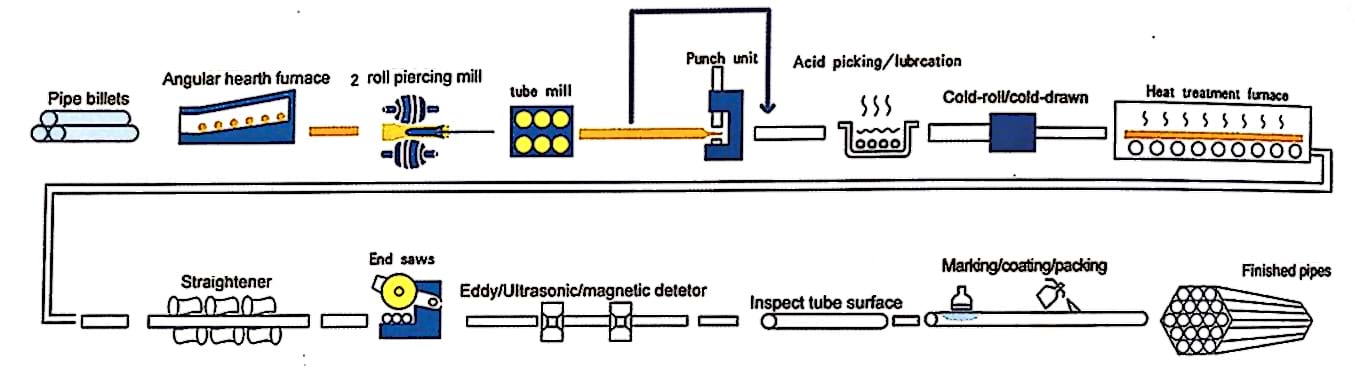

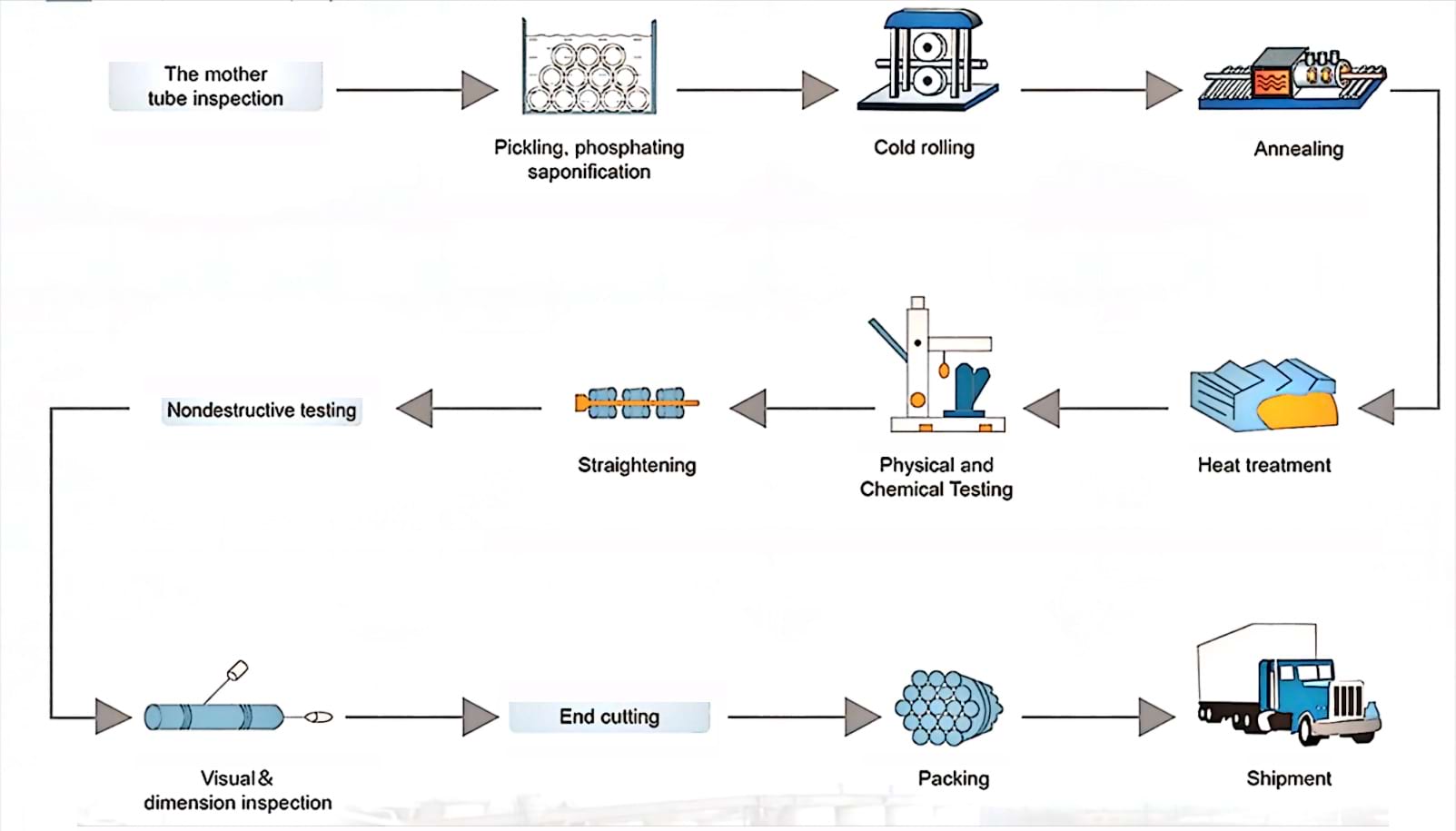

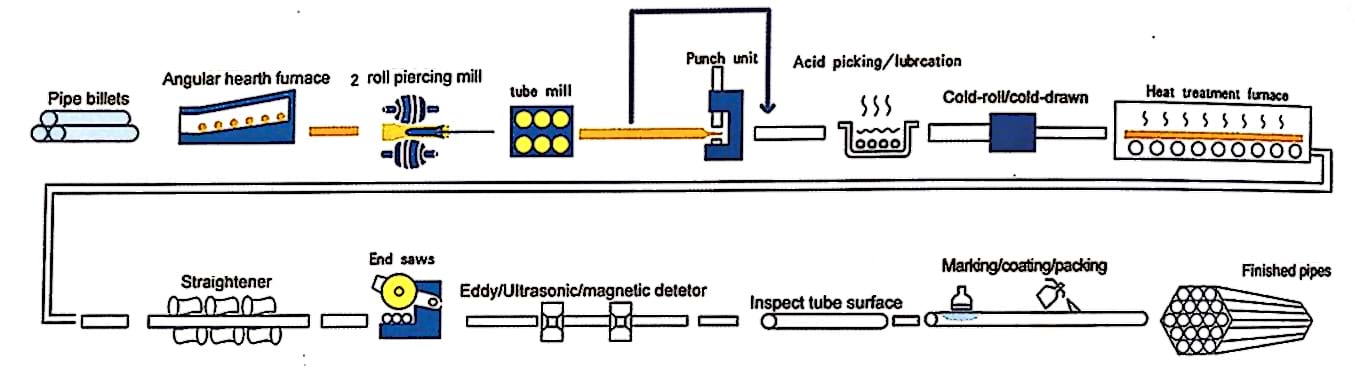

Seamless precision tubes are high-precision tubes designed for use in various applications where tight tolerances, smooth surfaces, and specific mechanical properties are crucial. These tubes are typically manufactured through a cold-drawing or cold-rolling process, which allows for excellent dimensional accuracy and surface finish.

Supply Range Of Precision Tube

Material: 10, 20, 35, 45, 4130, ST30AL, ST35, ST45,ST52, E215, E355 etc

Standard: ASTM A 519, DN2391, EN10305, EN 10305-4, GB/3639, Clients special requirements

Delivery heat tratment status:

Cold drawn/hard:(+C)

Cold drawn/Soft:(+LC)

Cold drawn and stress released:(+SR)

Normalizing:(+N)

Annealed:(+A)

Size: OD- .6-121mm, WT 0.08-18mm

Grade | Delivery Status |

Cold drawn/hard+C | Cold drawn/Soft+LC | Stress released annealing+SR | Annealing+A | Normalizing+N |

Rm MPa | A % | Rm MPa | A % | Rm MPa | ReH MPa | A % | Rm MPa | A % | Rm MPa | ReH MPa | A % |

No less than |

10 | 430 | 8 | 380 | 10 | 400 | 300 | 16 | 335 | 24 | 320~450 | 215 | 27 |

20 | 550 | 5 | 520 | 8 | 520 | 375 | 12 | 390 | 21 | 440~570 | 255 | 21 |

35 | 590 | 5 | 550 | 7 | -- | -- | -- | 510 | 17 | ≥460 | 280 | 21 |

45 | 645 | 4 | 630 | 6 | -- | -- | -- | 590 | 14 | ≥540 | 340 | 18 |

Q345B | 640 | 4 | 580 | 7 | 580 | 450 | 10 | 450 | 22 | 490~630 | 355 | 22 |

Advantages Of Precision Tubes

In industries such as aerospace, automotive, and instrumentation, where precision is crucial, the tight tolerances of precision tubes make them well-suited for specialized applications that demand high accuracy.

Precision tubes are manufactured with tight tolerances, ensuring high dimensional accuracy, uniform wall thickness and excellent surface finish.

Precision tubes can be produced from various materials, including carbon steel, stainless steel, alloys, and non-ferrous metals. This allows for tailoring the tube's properties to meet specific industry standards and application demands.

Precision Rolling

The precision rolling process, also known as precision tube rolling or cold rolling, is a manufacturing technique used to produce seamless tubes with tight tolerances and high surface quality.

Precision Drawing

Precision Rolling&Drawing Equipment

Hydraulic Cold Drawing Machine

10-Roller Straighter

Hydro Test Machine