Application Of Seamless Stainless Steel Pipe

Seamless stainless steel pipes are extensively used in the oil and gas industry for conveying fluids such as oil, gas, and corrosive substances, also in chemical and petrochemical plants for transporting corrosive chemicals and fluids, in the food and beverage industry for conveying liquids and gases, in the aerospace industry for applications such as aircraft hydraulic systems, fuel lines, and structural components,etc.

Categories Of Seamless Stainless Steel Pipe

-Austenitic Stainless Steel Seamless Pipe

Austenitic stainless steel has austenite as its primary phase at both elevated and room temperature. A stable austenite structured steel contains about 18% Cr, 8% ~ 10% Ni and about 0.1% C. Chrome-nickel austenitic stainless steel including the most familiar stainless steel 18Cr-8Ni (TP304) and the series of high Cr-Ni steel developed by increase Cr, Ni contents and add Mo, Cu, Si, Nb, Ti and other elements. Austenitic stainless steel is characterized by non-magnetic, high plasticity and ductility but lower strength. It can be only strengthened via cold working (by adding S, Ca, Se, Te and etc, austenitic stainless steel can have excellent machinability).

Grades:304/L/H/LN, 316/L/H/LN/Ti/LMod, 310S/H, 317/L, 321/H, 347/H/HFG,S30815

Specifications:

ASME SA213 Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASME SA312 Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A269 Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

EN1016-5 Seamless steel tubes for pressure purposes Technical delivery conditions Part 5: Stainless steel tubes

Features:

1.Excellent corrosion resistance

2.Good for cold working or hot working

3.High plasticity and ductility

4.Optimum general performance

5.A wide range of applications

-Super Austenitic Stainless Steel Seamless Pipe and Tube

When the pitting corrosion resistance equivalent value of Cr-Ni austenitic stainless steel is greater than or equal to 40%, it can be called super austenitic stainless steel. Super austenitic stainless steel is mainly developed to solve the defects of pitting corrosion resistance, crevice corrosion resistance and poor thermal stability of the original high molybdenum (more than 4%) Cr-Ni austenitic stainless steel under severe corrosion conditions containing chloride ions.

Grades:N08366,N08367,N08904(904L), N08925,N08926,S31254

Specifications:

ASME SA213 Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASME SA312 Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A269 Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASME SB677 Specification for UNS N08904, UNS N08925, and UNS N08926 Seamless Pipe and Tube

ASME SB690 Specification for Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and UNS N08367) Seamless Pipe and Tube

Features:

1.Superior resistance to chloride pitting, crevice corrosion in aggressive environment

2.Good mechanical properties with high yield strength

3.Excellent machinability

-Duplex Stainless Steel Seamless Pipe and Tube

Duplex Stainless Steel (DSS, short for Duplex Stainless Steel), refers to the ferrite and austenite each account for about 50%, the content of general is a youthful appearance also need to achieve at least 30% of the Stainless Steel. It is alloyed with 18%-28% Cr and 3%-10% Ni in the condition of low C, Some steels also contain the alloy elements such as Mo, Cu, Nb, Ti and N, etc.

When the pitting resistance of duplex stainless steel is higher than 40% (PREN=[Cr]+3.3[Mo]+16[N]), it can be called super duplex stainless steell.

Duplex stainless steel (DSS) is featured with structure of two phases (α and γ) and has characteristics of both ferritic and austenitic stainless steel. It has good corrosion resistance and high strength. It is alloyed with 18%-28% Cr and 3%-10% Ni in the condition of low C. Some steels also contain the alloy elements such as Mo, Cu, Nb, Ti and N, etc.

Comparing with ferritic stainless, duplex stainless steel has higher plasticity, ductility and better intergranular corrosion resistance and weldability. It keeps same 475℃ brittleness with ferritic stainless and high thermal conductivity. Duplex has improved yield strength, resistance to intergranular corrosion, stress corrosion, corrosion fatigue and abrasion & corrosion compared with austenitic stainless steel.

Grades:S31500,S31803,S32205,S32304, S32750, S32760

Specifications:

ASME SA789 Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

ASME SA790 Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

GB/T 21833-2008 Austenitic-Ferritic (duplex) grade stainless steel seamless tubes and pipes

EN1016-5 Seamless steel tubes for pressure purposes Technical delivery conditions Part 5: Stainless steel tubes

Features:

1.Superior resistance to general and local corrosion, especially to stress corrosion, pitting corrosion, crevice corrosion, corrosion fatigue and abrasion & corrosion.

2.Good weldability

3.Good mechanical properties

4.Excellent intergranular corrosion resistance

5.High cost-effectiveness, long life time

-Ferritic Stainless Steel Seamless Pipe and Tube

Ferritic stainless steel (400) of chromium content in 15% ~ 30%, with a body centered cubic crystal structure. It is generally do not contain nickel, sometimes also contains a small amount of Mo,Ti ,Nb, such as this kind of steel has a large thermal conductivity, small expansion coefficient, excellent oxidation resistance, good resistance to stress corrosion, etc. It is mainly used in the manufacture of atmospheric water, vapor water, resistant and oxidizing acid corrosion parts. Ferritic stainless steel has wide range application, excellent comprehensive performance, is the most important section of the nickel stainless.

Ferritic stainless steel is a type of chromium alloy that has ferritic structure at elevated and room temperature with body-centered cubic crystal structures. It has a chemical composition consisting of C≤0.02% and Cr 10.5%~32% and cannot be hardened by heat treatment. Ferritic stainless steel is used in comprehensive applications with excellent general properties, and is taken as a kind of primary nickel-saving stainless steels.

Grades:409, 410,439, 444

Specifications:

ASME SA213 Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASME SA731 Specification for Seamless, Welded Ferritic, and Martensitic Stainless Steel Pipe

Features:

1.High thermal conductivity

2.Low expansion coefficient

3.Good antioxidation property

4.Excellent stress corrosion resistance

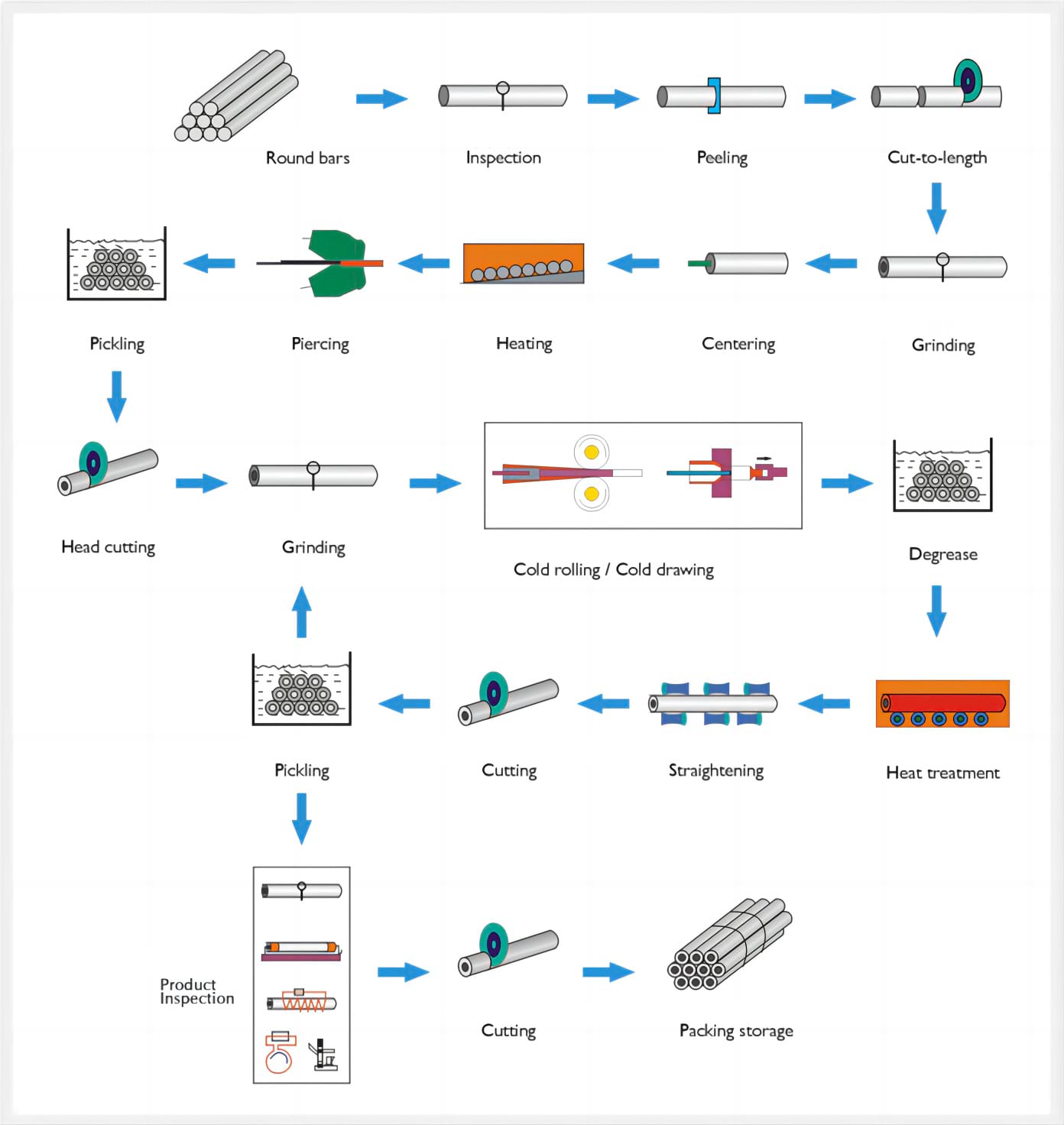

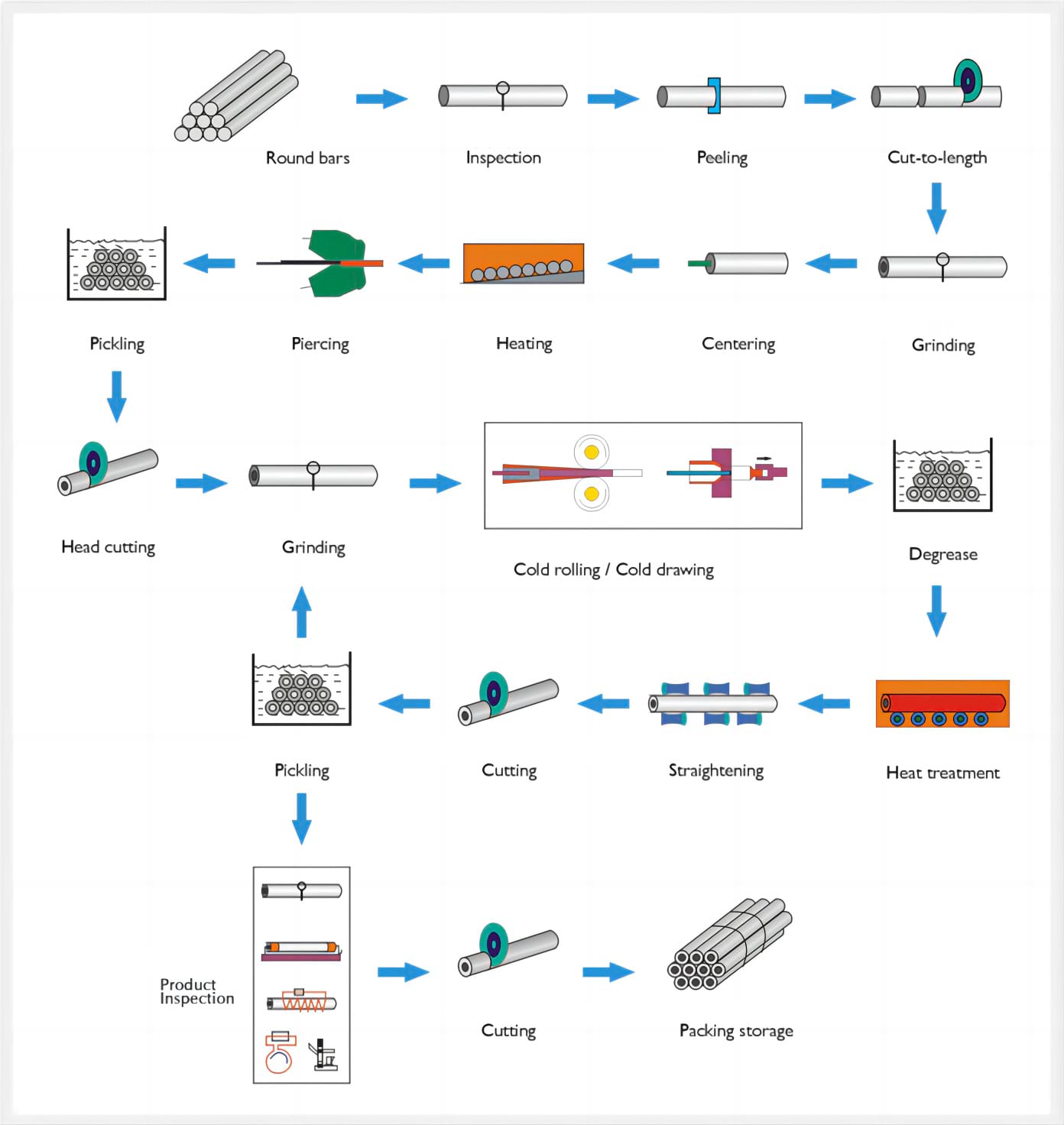

Manufacturing Process of Seamless Stainless Steel Pipe