API 5L welded line pipes are commonly used in the oil and gas industry for the transportation of fluids such as oil, gas, and water. These pipes can be manufactured through various welding processes, such as electric resistance welding (ERW), longitudinal submerged arc welding (LSAW), and spiral submerged arc welding (SSAW).

Application of Welded Line Pipe

API 5L welded line pipes are commonly used for the construction of long-distance oil and gas pipelines. They provide a cost-effective and reliable means of transporting hydrocarbons from production facilities to refining and distribution centers, which are also utilized in the construction of offshore oil and gas platforms.

Usage of Pipes: Oil and gas line pipe, Pilling pipe, Structure pipe, Water pipe, etc.

Supply Range of Welded Line Pipe

Manufacturing Process: Electric resistance welding (ERW), longitudinal submerged arc welding (LSAW), and spiral submerged arc welding (SSAW).

Product specification level: PSL1, PSL2

Grades:

API 5L: Grade A, B, X42, X46, X52, X56, X60, X65, X70, X80(suffix with R-As rolled, N-Normalizing rolled, Normalized formed, Normalized, Q-Tempered and quenched, M-Thermomechanical rolled or thermomechanical formed, S-Sour Service)

ASTM A53: GR A, GR B, GR C

EN: S275, S275JR, S355JRH, S355J2H

Diameter: 1/2in to 60in

Thickness: SCH10, SCH20, SCH40, STD, SCH 80, SCH XS, SCH 160.

Length: 6m or 11.8m or customized

Pipe End: Plain-end or beveled end with caps

Surface: Bare, clear varnished, black coating, FBE, 3PE, etc.

Marking: standard or customized

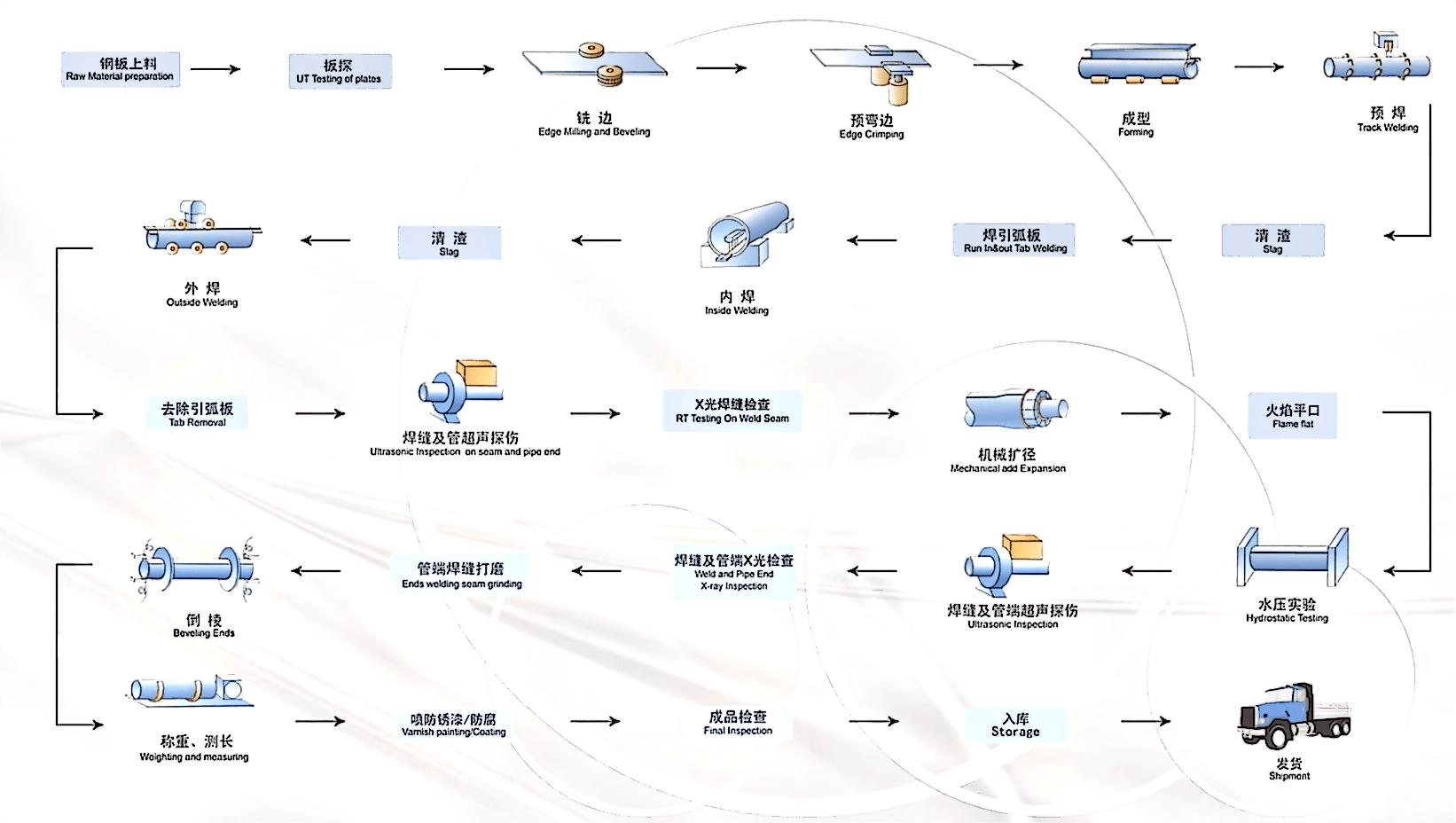

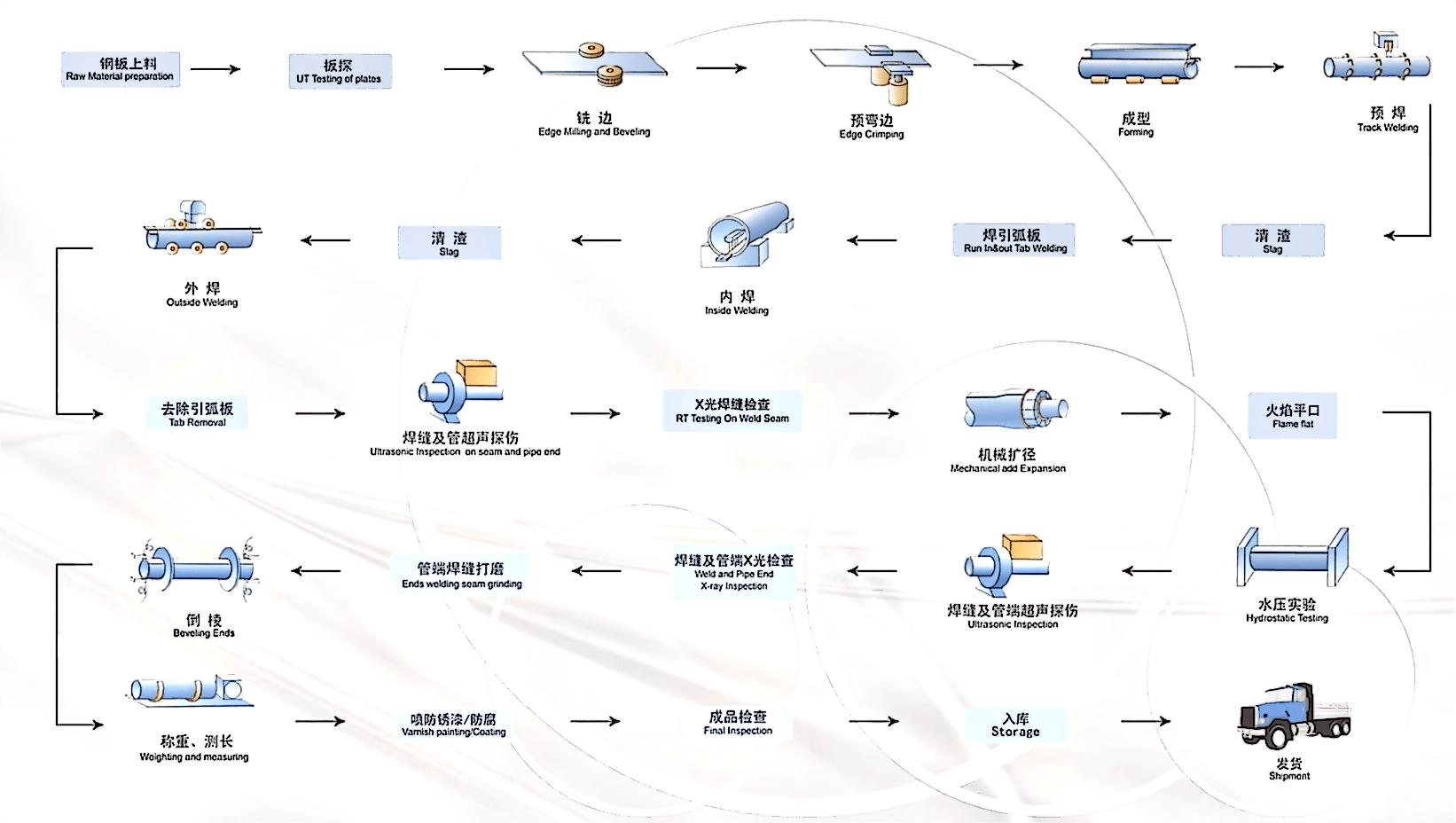

Manufacturing Process of Welded Line Pipe

Electric resistance welding (ERW)

Longitudinal submerged arc welding (LSAW)

Spiral submerged arc welding (SSAW)

Sizes Available for ERW/LSAW/SSAW

Our different manufacturing process can meet different demand of sizes from customers.

ERW: OD:Ф273~Ф762mm, WT:4.8~ 25.4mm, length 6-12.5m

LSAW: OD:Ф406~Ф1626mm, WT:6.4~ 32mm,length 6-12.5m

SSAW: OD:Ф508~Ф2236mm, WT:6.4~ 25.4mm,length 6-12.5m

Process Flow of Welded Pipe