Geological Drilling Pipe(General geological drill pipe)

Geological drilling pipes, also known as drill pipes or drill rods, are crucial components in the process of extracting core samples from the Earth's subsurface for geological and environmental studies. These pipes are typically made of high-strength materials, such as steel, to withstand the demanding conditions of drilling.

Outer diameter: Φ33mm~Φ127mm;Wall thickness: 5.0mm~10.0mm;

Length:6~12m

Main grades or materials:

ZT380, ZT490, ZT520, ZT540, ZT590, ZT640, ZT740 standard

Mechanical properties

Grade | Yield Strength MPa | Tensile Strength MPa | Elongation % |

ZT380 | ≥380 | ≥640 | ≥14 |

ZT490 | ≥490 | ≥690 | ≥12 |

ZT520 | ≥520 | ≥780 | ≥15 |

ZT540 | ≥540 | ≥740 | ≥12 |

ZT590 | ≥590 | ≥770 | ≥12 |

ZT640 | ≥640 | ≥790 | ≥12 |

ZT740 | ≥740 | ≥840 | ≥10 |

OD Tolerance: -0.5%D~+1.0%D

WT Tolerance: -10%S~+12.5%S

Straightness: ≤1.0~1.3mm/m

Service environment

Geological drill pipe is mainly used for transmitting power and transporting dilling mud which need to have good mechanical properties. It can be applied to the environment with high temperature and corrosive medium(such as H⊃2;S, CO⊃2;).

Geological Drilling Pipe(Trenchless drill pipe)

HDD (Horizontal Directional Drilling) drill rods are specialized tools used in the horizontal directional drilling process. HDD is a trenchless technology used for the installation of underground utilities, such as pipelines and cables, without the need for traditional open-cut methods.

The main grades or materials: G105, s135, v150

Standards:

API SPEC 5D: 2001<Specification for Drill Pipe>

API Bul 5C2: 1999<The performance of casing, tubing and drill pipe>

SY/T 6417-2009<The performance of casing, tubing and drill pipe>

SY/Y 6898.2-2013<The technical specification of special pipe for petroleum and natural industry part2: orientation crossing with drill pipe>

Product Feature

Mechanical properties

Grade | Yield Strength MPa | Tensile Strength MPa | Elongation % | Charpy impact(J) L-10-21℃ |

G105 | 724~931 | ≥793 | ≥15 | 54 |

S135 | 931~1138 | ≥1000 | ≥13 | 54 |

V150 | 1034~1184 | ≥1103 | ≥13 | 80 |

Dimensional accuracy

OD Tolerance: -0.5%D~+1.0%D

WT Tolerance: ≥-12.5%S

Full length straightness: ≤0.2%L

Service environment

Geological drill pipe is mainly used for transmitting power and transporting dilling mud which need to have good strength, ductility, tenacity, high wear-resisting,anti-fatigue reserve and corrosion resistance.

One-Piece Upsetted Horizontal Directional HDD Drill Rod

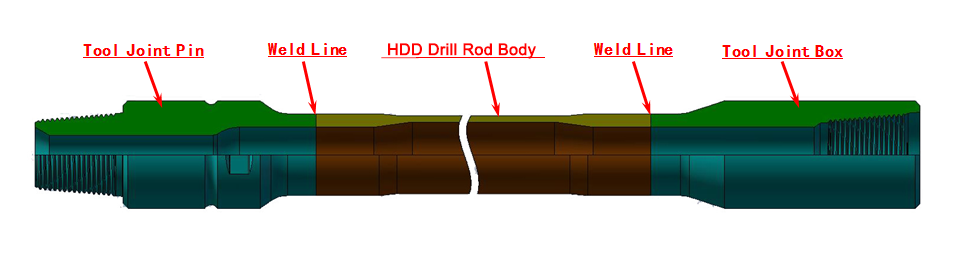

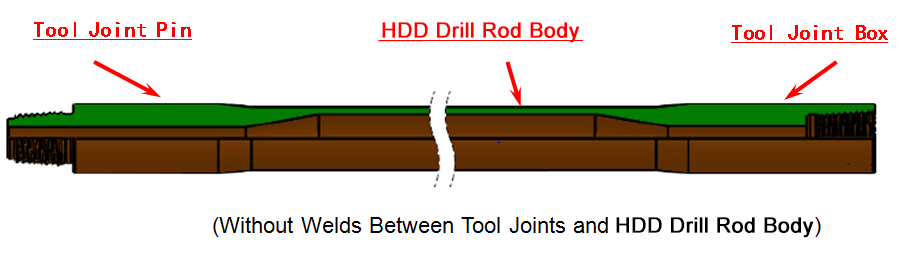

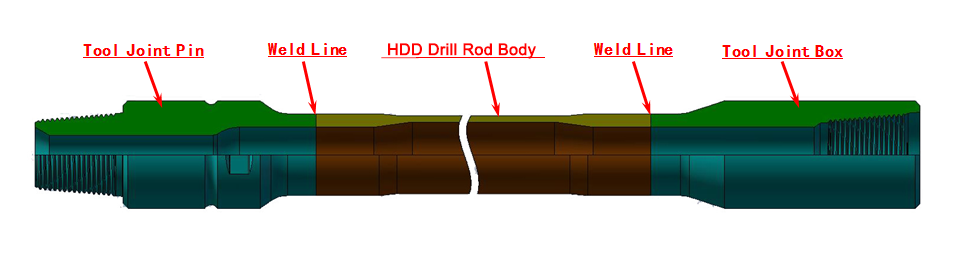

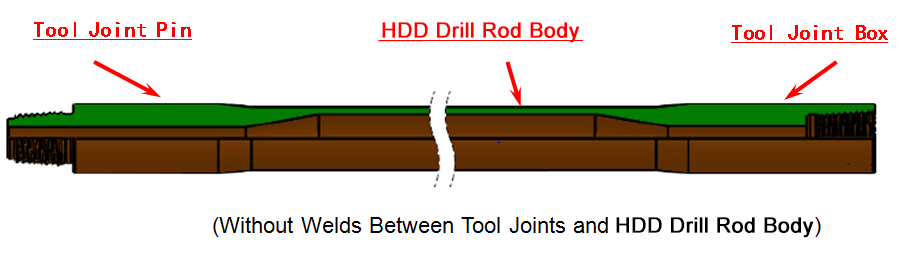

Friction Welding Horizontal Directional HDD Drill Rod