Coiled tubing (CT) is a continuous, long-length steel or composite tubing wound on a large reel. It is a versatile tool used in various oil and gas operations, particularly in well intervention and completion activities. Coiled tubing is commonly deployed in both onshore and offshore environments, and its flexible, continuous nature allows for a range of applications.

Application Of Coiled Tubing

Well Intervention: Coiled tubing is extensively used for well intervention operations such as clean outs, milling, logging, perforating, and hydraulic fracturing.

Completion Operations: In well completion, coiled tubing can be used for tasks like running and pulling plugs, setting and retrieving tools, and various other tasks to prepare the well for production.

To Install Wires And Pipes: Electrical wires or hydraulic lines can be installed in the coiled tubing string and terminate at the coiled tubing reel. Operation control and power functions can be installed between the down hole tool assembly and surface equipment.

Specifications Of Coiled Tubing

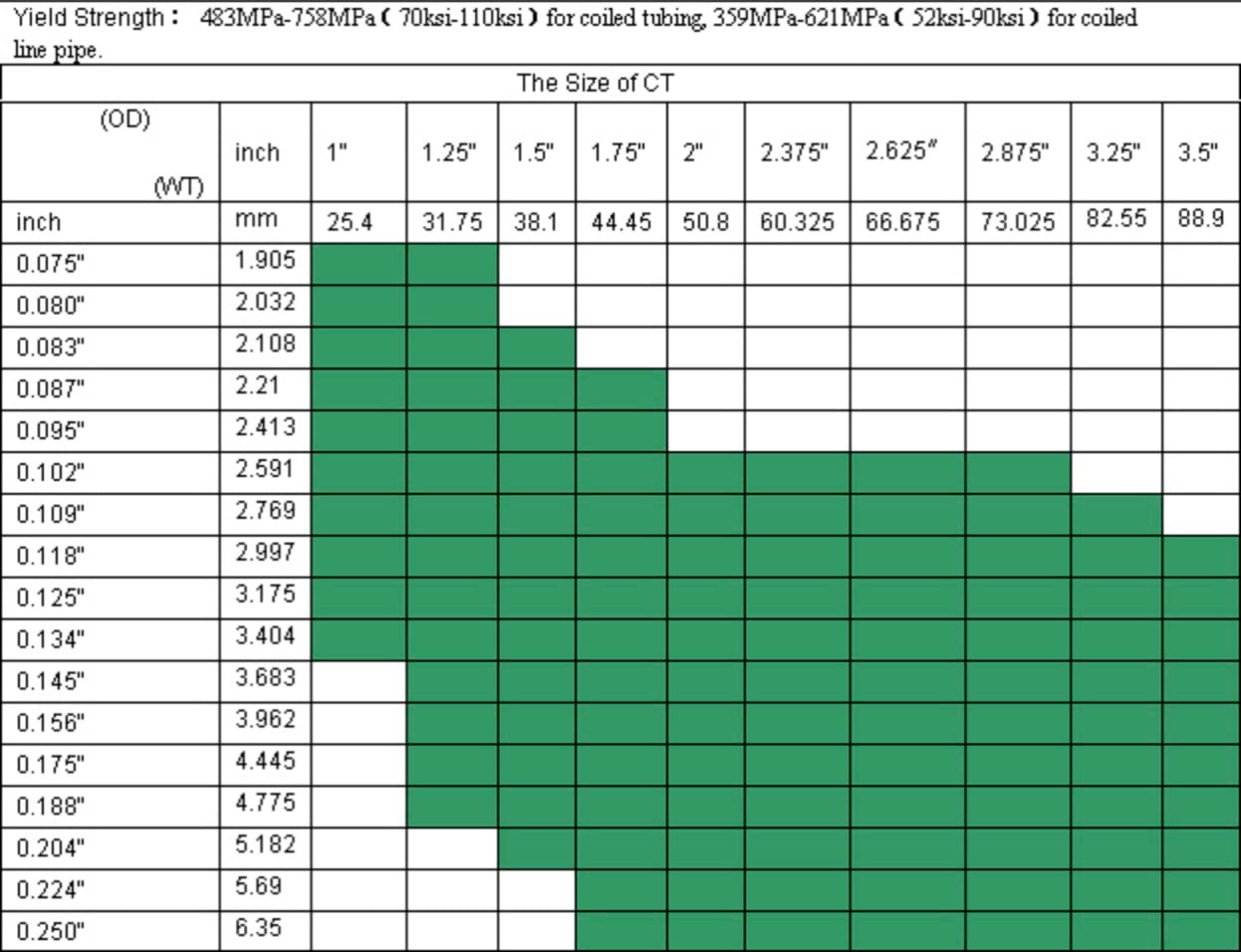

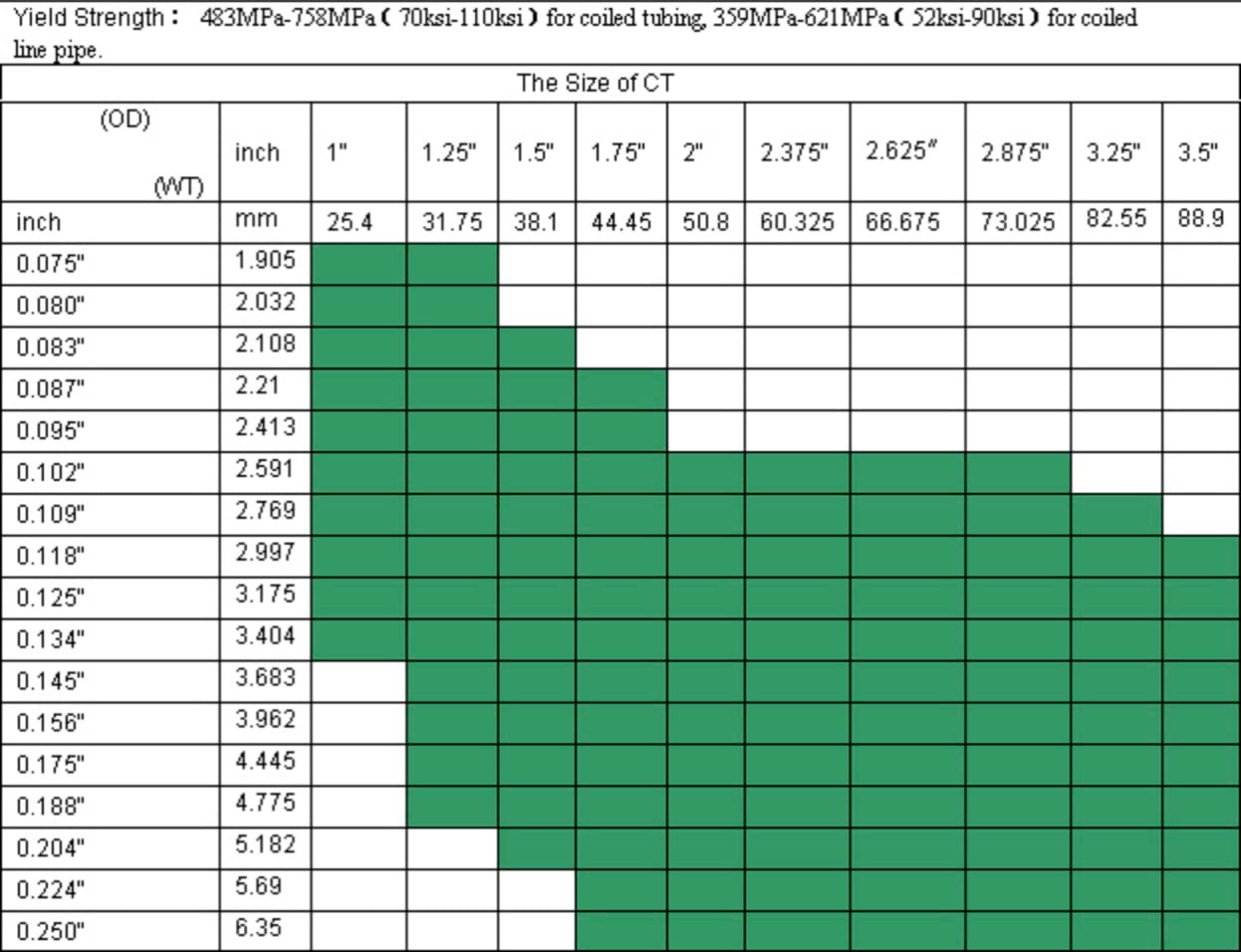

Coiled Tubing OD: 25.4mm-88.9mm

Thickness: 1.91mm-6.435mm

Pipe Length: Max 8000m

Specification: API Spec 5ST, API Spec 5LCP

Steel Grade: CT70,CT80, CT90, CT100, CT110, X52C-X90C

Yield Strength: Coiled tubing 483MPa-758MPa (70ksi-110ksi), coiled line pipe 359MPa-621MPa (52ksi-90ksi).

Delivery Of Coiled Tubing

Advantages Of Coiled Tubing:

Continuous Length: The continuous nature of coiled tubing eliminates the need for joints, reducing the risk of connection-related issues and simplifying the deployment process.

Time Efficiency: Coiled tubing operations are often faster than traditional jointed tubing operations, reducing overall rig time.

Versatility: Coiled tubing can be used in various down hole applications without the need for tripping in and out of the well.