Blind Flange

This flange is used to seal the end of pipes systems and prevent flow, making it easy to conduct pressure tests. They are easy to work around as they allow convenient access to pipes.

NPS: 1/2" to 60”

Pressure Rating: Class 150,Class 300,Class 600,Class 900Class 1500,Class 2,500.

Connection Face: RF/RTJ

Material:

Carbon Steel: ASMT A105/N, ASTM A350 LF2 CL1, ASTM A694 F52/F60/F65/F70

Stainless Steel: ASTM A182 F304/F304L/F310/F316/F316LF317/F321

Alloy Steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil, black paint, vellow paint, hot dip galvanized. electrolytic zinc and epoxy resin coatings

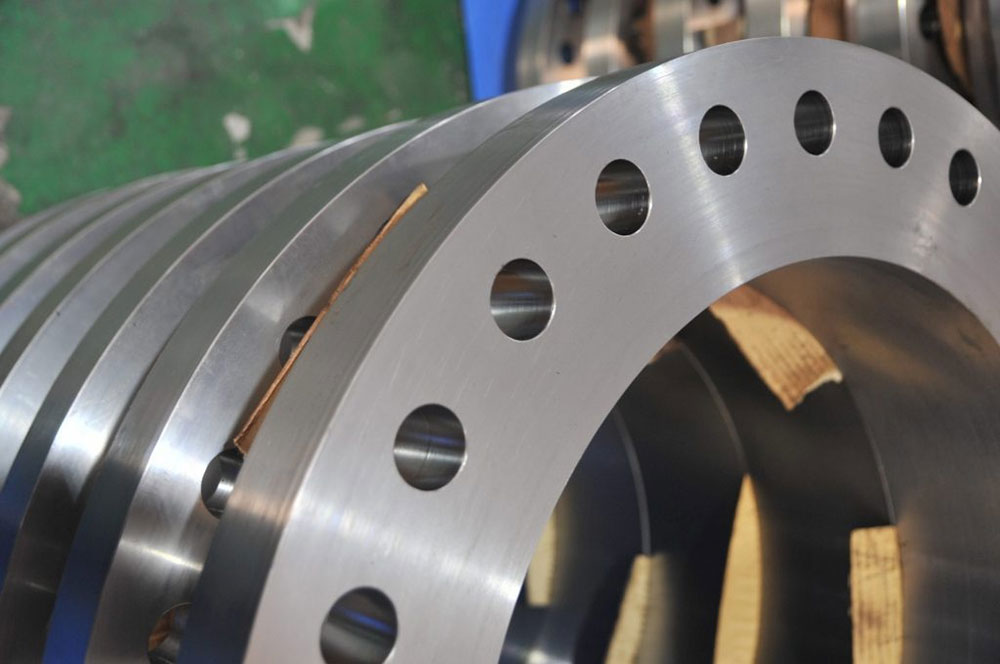

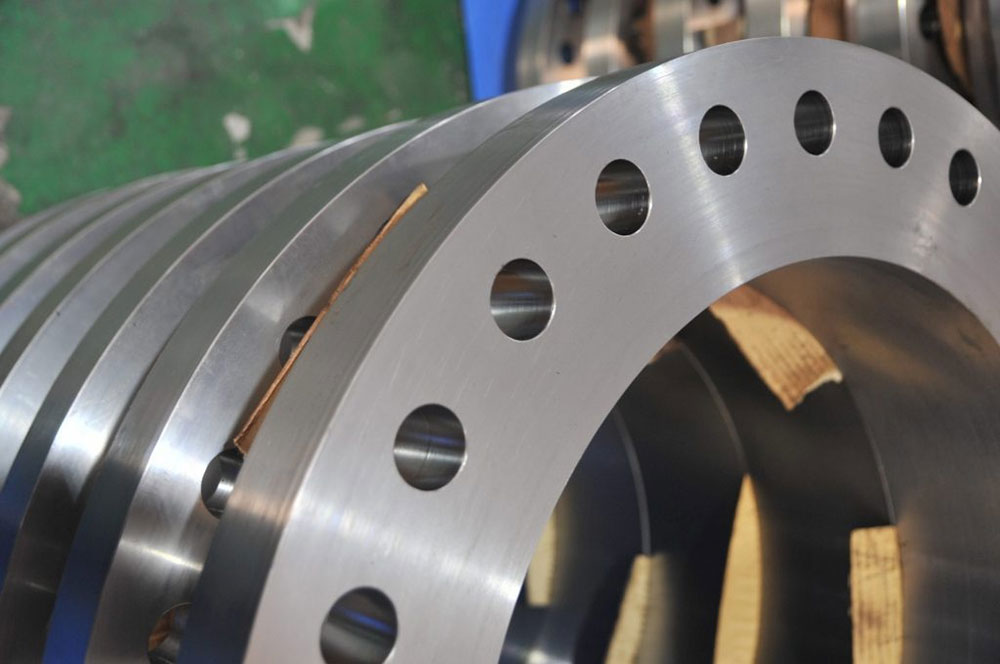

Lap Joint Flange

Used in conjunction with a universal stub end fittings this flange is often used to avoid issues that could arise with the alignment of bolt holes. Stub end fittings are welded to the pipe, and rotate around the stub end. They are commonly used in applications where the juncture does not come in contact with the fluid or gas marking then reusable, and they are also beneficial in applications keeping down expenses when exotic metals are used.

NPS: 1/2" to 24"

Pressure Rating: Class 150,Class 300,Class 600,Class 900,Class 1500,Class 2,500.

Connection Face: FF

Material:

Carbon steel: ASMT A105/N,ASTM A350 LF2 CL1,ASTM A694F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil, black paint, yellow paint, hot dip galvanized, electrolytic zinc and epoxy resin coatings

Long Welding Neck Flange

Long welding neck flange is normally used for nozzles on pressure vessels and rarely used with pipe.The hub of the flange is straight and thicker than the taper of the weld neck flange.

NPS: 1/2" to 24"

Pressure Rating: Class 150,Class 300,Class 600,Class 900,Class 1.500,Class 2.500.

Connection Face: RF/RTJ

Material:

Carbon steel: ASMT A105/N.ASTM A350 LF2 CL1, ASTMA694 F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304 /F310/F316/F316 /F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil,black paint,yellow paint,hot dip galvanized,electrolytic zinc and epoxy resin coatings

Orifice Flange

These are widely used in conjunction with orifice meters for measuring the rate of flow of liquids and gases. They are basically the same as standard welding neck and slip-on flanges except for the provision of radial, tapped holes in the flange ring for meter connections and additional bolts toact as jack screws to facilitate separating the flanges for inspection or replacement of the orifice plate. In choosing the type of orifice flange, the considerations affecting the choice of welding neck and slip-on standard flanges apply with equal force.

NPS: 1/2" to 24"

Pressure Rating: Class 300,Class 600,Class 900,Class 1500,Class 2500

Connection Face: RF/RTJ

Material:

Carbon steel: ASMT A105/N, ASTM A350 LF2 CL1, ASTM A694 F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil, black paint,yellow paint,hot dip galvanized,electrolytic zinc and epoxy resin coatings

Slip-on Flange

This type of flange, as implied by its name, has a diameter slightly larger than the pipe so that it can slide over the pipe to fit snugly.Though they are thinner than most other flanges, but they are strong, dependable, and cost-effective.

Carbon steel: ASMT A105/N,ASTM A350 LF2CL1, ASTMA694 F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil, black paint, yellow paint,hot dip galvanized,electrolytic zinc and epoxy resin coatings

Socket Welding Flange

Socket welding flanges are typically used on smaller sizes of high pressure pipes. These pipe flanges are attached by inserting the pipe into the socket end and applying fillet weld around the top.This allows for a smooth bore and better flow of the fluid or gas inside of the pipe.

NPS: 1/2" to 3”

Pressure Rating: Class 150,Class 300,Class 600,Class 900, Class 1,500

Connection Face: RF/RTJ

Material:

Carbon steel: ASMT A105/N,ASTM A350 LF2 CL1ASTM A694 F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oi,black paint yellow paint, hot dip galvanized,electrolytic zinc and epoxy resin coatings

Spectacle Blind Flange

It is a combination of the two that can be rotated to function as Single Bind or a Ring Spacer. This kind of flange is generally a piece of metal than is cut to fit between two pipe flanges and usually sandwiched between two gaskets a spectacle blind is often made from two metal discs that are attached to each other by a small section of steel.The Sharp is similar to a pair of glasses or spectacles - hence the name spectacle blind flange.One end of the blind will have an opening to allow flow through the pipe during operation and the other end is solid to block flow during maintenance. They are generally installed as a permanent device to separate process piping system.

The whole idea of a spectacle blind is so that one can be absolutely sure that an item of equipment is properly and securely blanked off with no possibility of any flow or leakage through a valve during maintenance. The flow can be diverted to other items of equipment but not just by passed around the blank as this would compromise the safety function of the spectacle blind. The flow has to valve off and pressure relieved prior to loosening flange bolts and swinging the blind.

NPS: 1/2" to 24”

Pressure Rating: Class 150,Class 300,Class 600,Class 900,Class 1.500,Class 2500

Connection Face: RF/Female Ring-Joint Facing/Male Oval Ring-Joint Facing

Material:

Carbon steel: ASMT A105/N,ASTM A350 LF2 CL1, ASTM A694 F52/F60/F65/F70 Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil, black paint,yellow paint, hot dip galvanized,electrolytic zinc and epoxy resin coatings

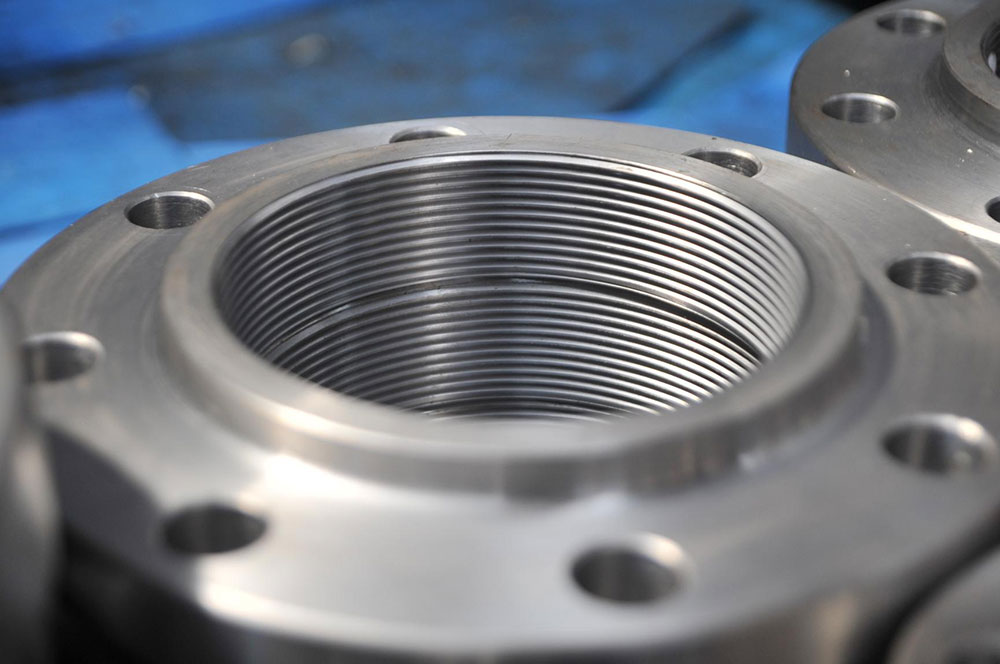

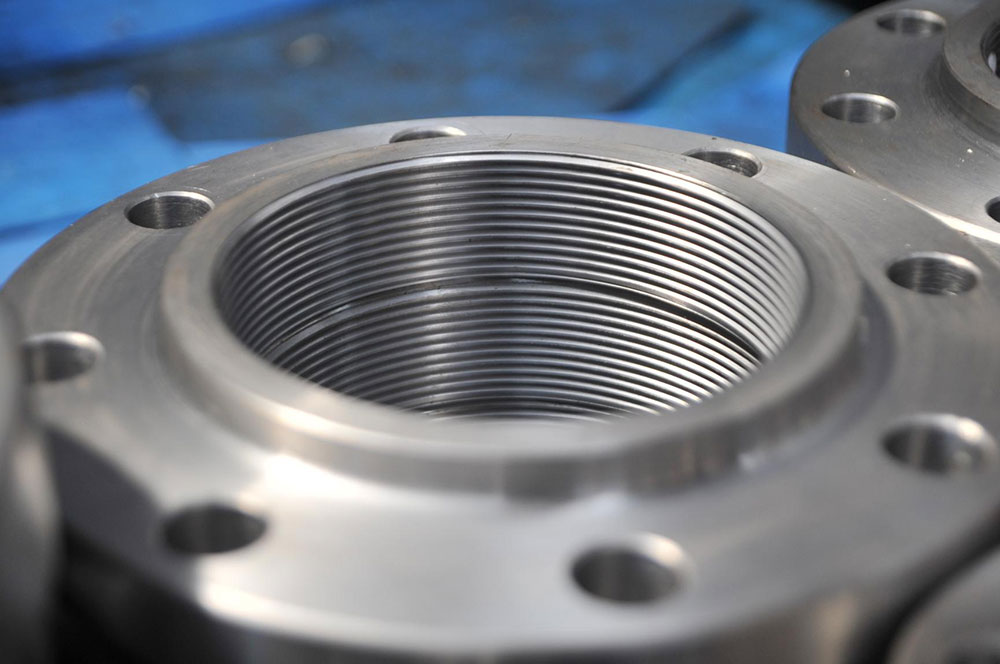

Threaded Flange

Threaded flange (Screwed flange) is similar to the Slip-On flange, but is popular because it can be attached without welding since it is designed with tapered threads to work with pipes that have external threads. Also low cost, it’s great for small pipes and highly combustible areas where welding is dangerous.

Carbon steel: ASMT A105/N, ASTM A350LF2 CL1, ASTM A694F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil, black paint, yellow paint, hot dip galvanized,electrolytic zinc and epoxy resin coatings

Welding Neck Flange

This flange is often used for high-pressure applications to reduce the concentration of stress, this type of flange has a neck that is welded to the base of pipe. One of the most popular options for high-pressure systems, the tapered hub offers strength and flexibility.

NPS: 1/2" to 60”

Pressure Rating: Class 150,Class 300, Class 600,Class 900, Class 1500, Class 2500

Connection Face: RF/RTJ

Material:

Carbon steel: ASMT A105/N. ASTM A350 LF2 CL1, ASTM A694 F52/F60/F65/F70。Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil, black paint, yellow paint, hot dip galvanized,electrolytic zinc and epoxy resin coatings

Reducing Flange

Reducing flanges are a little easier to bolt up than non-reducing flanges. They provide the most perfect solution when you need to connect different size flanges..These flanges are available in all types and pressures. Reducing flanges are fixed by welding,gluingor clamping flanges of equal dimensions, provided with different connecting pieces. They offer the simplest and least expensive method of mating two different sized flanges

Type of reducing flanges: welding neck,slip-on,threaded.

Pressure Rating: Class 150,Class 300,Class 600,Class 900,Class 1500,Class 2500.

Connection Face: RF/RTJ

Material:

Carbon steel: ASMT A105/N,ASTM A350 LF2 CL1,ASTM A694 F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil,black paint, yellow paint,hot dip galvanized,electrolytic zinc and epoxy resin coatings

Spacer&Spade Flange

In the oil and chemical process industries, a spade is a round piece of metal with a small tab that is placed in between two pipe flanges to give positive isolation from the center usually to prevent cross contamination between fluids or to allow work on the line.

NPS: 1/2" to 24"

Pressure Rating: Class 150,Class 300,Class 600, Class 900, Class 1500Class 2.500

Connection Face: RF/RTJ

Material:

Carbon steel: ASMT A105/N,ASTM A350LF2 CL1, ASTM A694F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil, black paint, yellow paint,hot dip galvanized,electrolytic zinc and epoxy resin coatings

Swivel Ring Flange

Swivel Ring Flange can be designed for any size and pressure rating to meet applicable dimensions and gasket types of any recognized flange specification,such as ASME B16.5,API 6A or MSS SP-44. Non standard Swivel-Ring Flange can also be custom-designed for certain applications; for example, applications involving large pipelines may incorporate features such as hub face profiles to aid axial alignment and Teflon rings between the SRF ring and hub to reduce rotational friction.

Carbon steel: A105,A350 LF2,C22.8,S355|R

Stainless steel: A182 F304/F304L/F316/F316L/F321

Alloy steel: F11.F12

Packing: plywood case or plywood pallet

Coating: Oil, black paint vellow paint, hot dip galvanized, electrolvtic zinc and epoxy resin coatings

F Nozzle Flange

The Full Body Type F Necks-F Nozzle Flanges connection provides the most reinforcement of all standard connections produced by us.The barrel outside diameter equals the outside diameter of the bolting flange. Within the flange hub area, the outside diameter of the barrel provides an automatic nut stop.A nut relief in the barrel, special bores and contoured bottoms are available upon request.

NPS: 1/2" to 24”

Pressure Rating: Class 150,Class 300,Class 600,Class 900,Class 1500,Class 2500.

Connection Face: RF/RTJ

Material:

Carbon steel: ASMT A105/N, ASTM A350 LF2 CL1,ASTM A694 F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil, black paint, yellow paint, hot dip galvanized, electrolytic zinc and epoxy resin coatings

Heavy Barrel Type HB Necks/Flange

The Heavy Barrel Type HB Necks adds additional reinforcement beyond the same size lighter wall standard LWN. Common standard lengths are available from stock and can be increased to any longer length to provide the offset needed. These connections are always supplied with a “Nut Stop"unless“Nut Relief" is requested.The inside diameter of these connections for 12” and below are provided with a S80 pipe size bores,14" and large HB Connections are offered with a bore equal to the nominal pipe size. Special bores, contoured bottoms and other custom variations of all kinds are available upon request.

NPS: 1/2" to 24"

Pressure Rating: Class 150,Class 300,Class 600,Class 900,Class 1500Class 2500.

Connection Face: RF/RTJ

Material:

Carbon steel : ASMT A105/N,ASTM A350 LF2 CL1,ASTM A694 F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22

Packing: plywood case or plywood pallet

Coating: Oil,black paint yellow paint, hot dip galvanized,electrolytic zinc and epoxy resin coatings

Studding Outlet Flange

Studding outlet flange is designed to be installation in the inside or outside of vessels and tanks The curving of the outlet should be ordered to fit the curvature of the shell,head or cone.These flanges can be ordered with test ho es (normally with a 1/8" tap unless specified. All classes 150 thru 2500 have a 1/16" raised face.

Carbon steel: ASMT A105/N,ASTM A350 LF2 CL,1ASTM A694 F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22.

Packing: plywood case or plywood pallet

Coating: Oil, black paint, yellow paint, hot dip galvanized, electrolytic zinc and epoxy resin coatings

V Nozzle Flange/V1 ,V2, V3 Necks

The Variable Body Type V1V2,V3 Necks-V Nozzle connection adds additional reinforcement beyond that of the TransitionalV1.V2 &V3 connection options.The“V" has a barrel wall thickness equal to the outside diameter of the mating flange. These items are made to order and can be provided with lengths of any size to provide the offset needed.These connections are always supplied with a“Nut Stop" unless “Nut Relief" is requested. The inside diameter of these connections for 12" and below are provided with a S80 pipe size bores14" and large HB Connections are offered with a bore equal to the nominal pipe size.Special bores, contoured bottoms and other custom variations of all kinds are available upon request.

NPS: 1/2" to 24"

Pressure Rating: Class 150,Class 300,Class 600,Class 900,Class 1500,Class 2.500.

Connection Face: RF/RTJ

Material:

Carbon steel: ASMT A105/N,ASTM A350 LF2 CL1,ASTM A694 F52/F60/F65/F70

Stainless steel: ASTM A182 F304/F304L/F310/F316/F316L/F317/F321

Alloy steel: ASTM A182 F11/F12/F22.

Packing: plywood case or plywood pallet

Coating: Oil, black paint, yellow paint, hot dip galvanized,electrolytic zinc and epoxy resin coatings