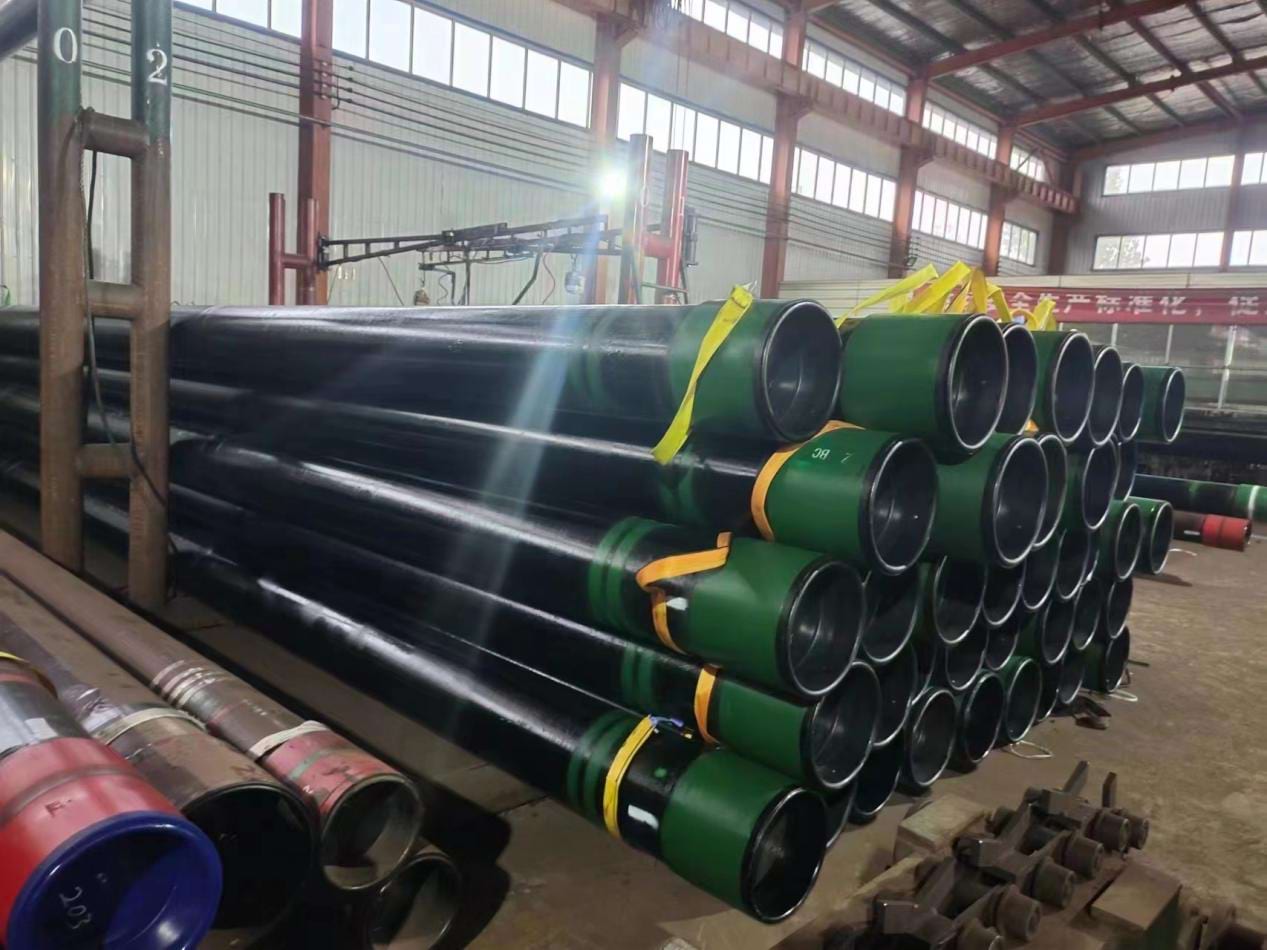

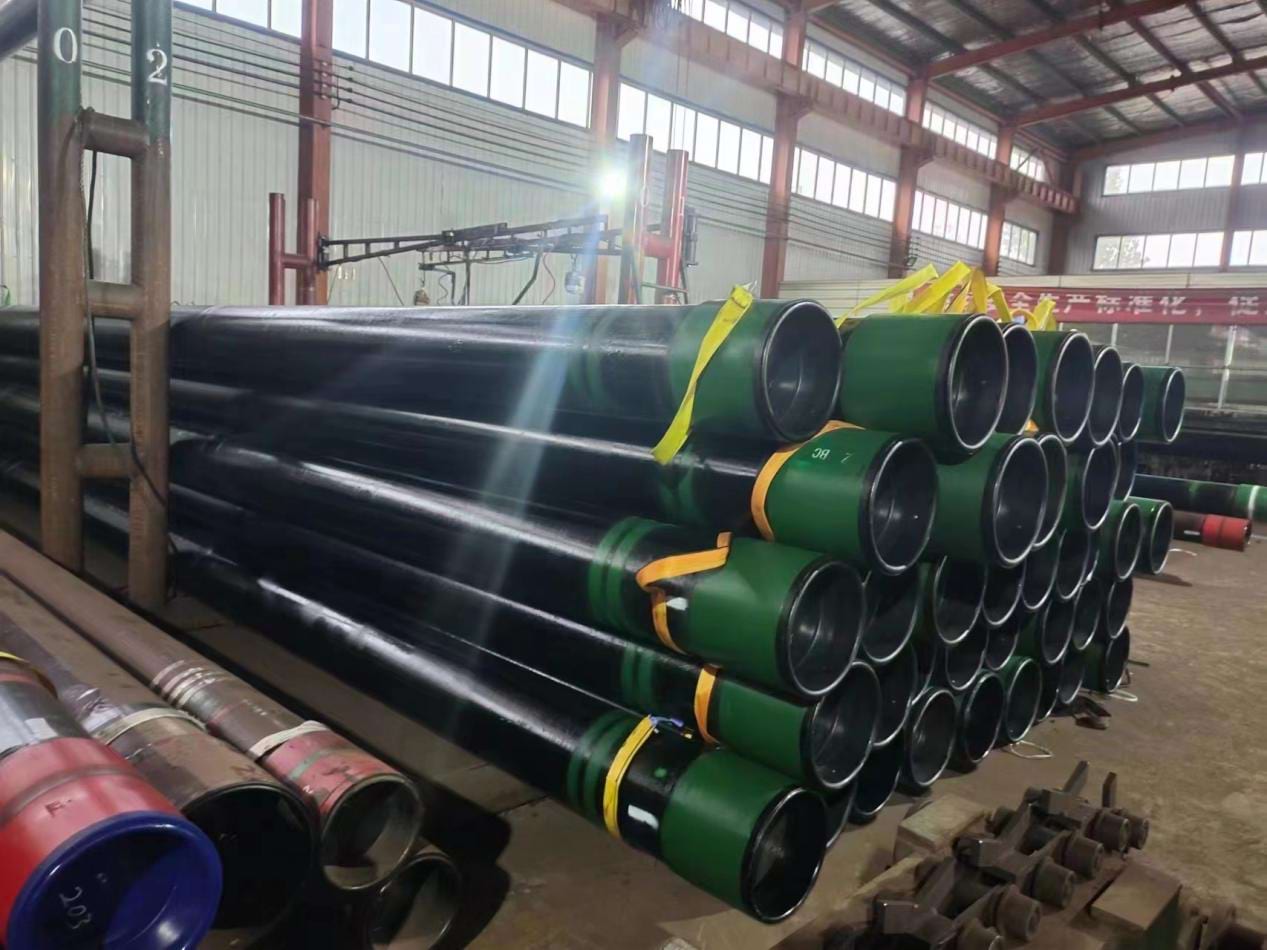

Application Of ERW Casing&Tubing

ERW (Electric Resistance Welded) casing and tubing are types of steel pipes commonly used in the oil and gas industry for various applications, including drilling, production, and transportation of fluids.

ERW pipes are manufactured by forming steel coils into a cylindrical shape, are often more cost-effective than seamless pipes, making them a popular choice for certain applications.

Specifications Of Casing&Tubing Available For ERW

API 5CT PSL1/PSL2: H40, J55, K55, N80, L80, P110

OD: 2 7/8” to 10 3/4”

Connection: P(Plain end), STC (short threads), LTC (long threads), BTC (buttress threads), EUE(end upset), NUE(non-upset)

Length: R2, R3

Choice Between ERW Or Seamless Casing&Tubing

The choice between ERW (Electric Resistance Welded) and seamless casing and tubing in oil and gas well construction depends on various factors, and each type has its advantages and considerations.

ERW: Electric resistance welding is a cost-effective manufacturing process, making ERW pipes generally more economical than seamless pipes. If cost is a significant factor, ERW casing and tubing may be a preferred choice.

Seamless: Seamless pipes involve more complex manufacturing processes, which can lead to higher production costs. As a result, seamless casing and tubing are often more expensive than their ERW counterparts.

ERW: While ERW pipes are strong and suitable for many applications, the welding process introduces a seam along the length of the pipe. This seam may have slightly lower mechanical properties compared to the rest of the pipe, and it can be a potential point of weakness. However, modern manufacturing and quality control processes have minimized these concerns.

Seamless: Seamless pipes are generally considered stronger because they lack the weld seam found in ERW pipes. The absence of a seam makes seamless pipes more uniform and less susceptible to potential weaknesses associated with welding.

ERW: ERW casing and tubing are well-suited for a wide range of applications, including conventional oil and gas wells. They are also commonly used in less demanding environments.

Seamless: Seamless pipes are often preferred in critical applications, high-pressure environments, and situations where the absence of a weld seam is crucial for safety and performance.