Coated line pipe refers to pipes used in pipelines for transporting fluids (such as oil and gas) that have been coated with protective materials. The coating is applied to the exterior or interior of the pipe to enhance its durability, resistance to corrosion, and overall performance.

Pipes can be applied with coatings include OCTG(casing and tubing), seamless line pipe, ERW pipe, LSAW pipe, SSAW pipe, and other seamless or welded pipes and pipe fittings in different industries.

Main Categories Of Coating On Pipes

Fusion-Bonded Epoxy (FBE): This is a popular coating for line pipes. FBE provides excellent corrosion resistance and is applied by heating the pipe and then applying a dry powder that melts and forms a protective layer upon cooling.

Three-Layer Polyethylene (3LPE) Or Polypropylene (3LPP): This coating system consists of three layers—an inner layer of fusion-bonded epoxy, a middle layer of adhesive, and an outer layer of polyethylene (3LPE) or polypropylene (3LPP). It offers good corrosion protection and mechanical resistance for steel pipes applied.

Concrete Weight Coating (CWC): In certain applications, pipes may be coated with a layer of concrete to add weight and stability to the pipeline on the seabed. This is common in offshore pipeline installations.

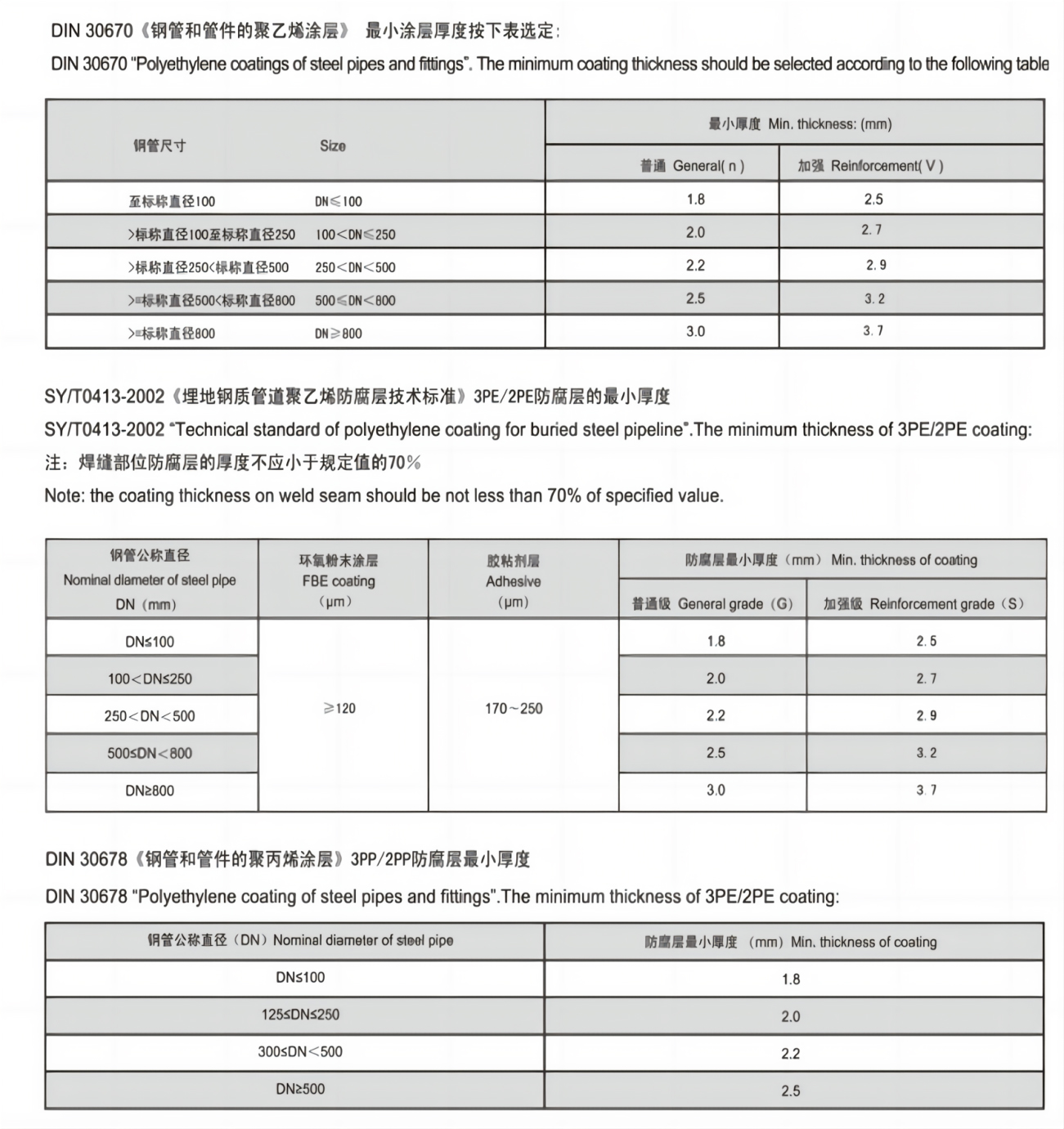

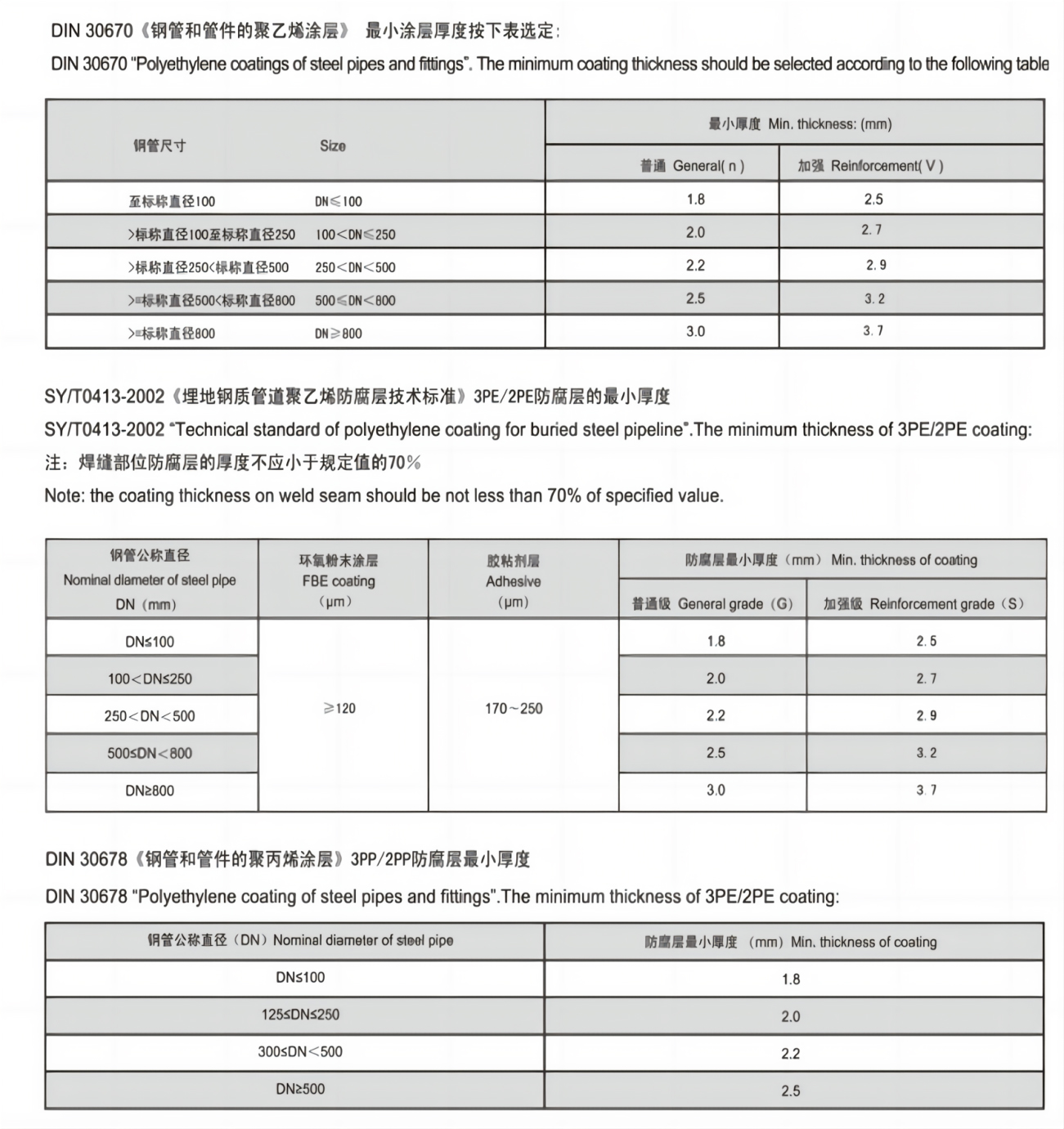

Coating On Pipes And Standards

Internal Coating |

Coating Type | Coating Standard |

Liquid Epoxy Coating | AWWA C210-2007 |

FBE | AWWA C 213-2001 |

Cement Mortar Lining | BS 534-1990, AWWA C205-2001 |

Bitumen Coating | BS 534-1990 |

External Coating |

Coating Type | Coating Standard |

3LPE/3LPP Coating | DIN 30670-1991, CAN/CSA Z245.21-2010,

ISO 21809-1-2009 SY/T 0413-2002 |

2LPE/2LPP Coating | SY/T 0413-2002, ISO 21809-1-2009 |

(Fusion-Bond Epoxy)FBE | SY/T 0315-2005, AWWA C 213-2001, CAN/CSA Z245.20-2010,

ISO 21809-2-2007, API RP 5L9-2001 |

Bitumen Coating/Enamel&tape

hot-applied | BS 534-1990, AWWA203-2002,AWWA 214-2000 |

Liquid Epoxy Coating | AWWA C210-2007 |

Polyurethane Insulated Coating | SY/T 0415-1996, CJ/T 114-2002, EN 253-1994 |

Quality Index Of External Coating Of Steel Pipes